Securing loads on trucks

This page has guidance on how to secure loads on trucks safely.

Chains and webbing with tensioning devices (tensioners) are commonly used to secure loads on trucks.

What is the problem?

Some types of tensioners have caused severe head, face and shoulder injuries to workers when used incorrectly and near misses are a common occurrence.

Tensioners include:

- webbing hand ratchets

- under-vehicle webbing winches

- chain dogs

- other chain tensioners.

What are the risks?

Using tensioners to tighten and release chains and webbing puts workers at risk of:

- musculoskeletal injuries, particularly to the back, shoulders and hands, from the repetitive force required to tighten chain tensioners, webbing winches and webbing hand ratchets

- pinched fingers

- falls from overbalancing

- fractures, contusions and lacerations from being struck by extension bar handles used with over-centre lever style tensioners (dogs), which can rebound and fly off the dog.

What is a solution to the problem?

Depending on the type of load being carried, the National Transport Commission's Load Restraint Guide (LRG) performance standards must be met to prevent loads from coming away from the truck during transit, or shift, causing vehicle instability.

Manufacturer's instructions should be followed while using tensioners. To eliminate or reduce the risk of injuries while using chains and webbing with tensioners, the following solutions can be used in order of priority – 1 being the preferred option.

1. Minimise the use of chains and webbing by using:

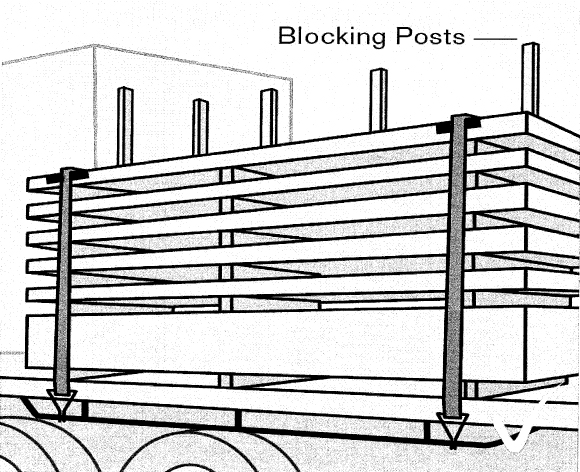

- systems to reduce or eliminate the need for chains and webbing, e.g. use a coil containment system, pin, pegs, posts, headboards or goose-neck on a drop-deck trailer to help block the load (see Figure 1)

- a truck that is custom-designed for loads, e.g. some pallet loads may suit a truck with combination internal side and middle expanding walls, combined with an inward-sloping floor and load-rated curtain.

Figure 1. Removable posts in a truck help block the load.

2. Use webbing straps instead of chains

- Webbing straps, if suitable for restraining a load, are lighter than chain. Webbing tensioners are also lighter to handle and, if fixed to the trailer, will not need handling. If webbing is used, two 2500 kg lashing capacity straps can often replace one regular (8 mm) chain with a 4000 kg lashing capacity. The load will need to be assessed, and webbing and chain should not be used together.

- As webbing is slightly elastic, it may stretch in transit and can also be damaged by sharp edges on loads.

- If using a hand ratchet with webbing:

- a pull-down webbing ratchet will reduce the risk of shoulder injuries because it will not need to be repeatedly pushed up

- it is easier to pull the ratchet handle (see Figures 2 and 3) when the strap length allows the ratchet to be between waist and shoulder height.

Figure 2. A pull-down hand ratchet reduces the risk of shoulder injury (note the extended top plate).

Figure 3. A ratchet cap/hat winch does not require the handle to be reinserted with every turn (note the black casing or 'cap').

- If using a winch with webbing:

- consider using a geared winch or one that does not require the removable handle to be reinserted with every turn. This reduces the risk of the handle coming off and unbalancing the worker. The handle should fit snugly on the socket or in the winch cap holes

- a geared winch requires less force and encourages better posture because workers do not need to repeatedly bend low when positioning or tensioning the handle. The more teeth a geared winch has, the less force is needed to gain high tension (see Figures 4 and 5).

Figure 4. This is a type of geared winch on the market. Geared winches generally do not require the handle to be repeatedly reinserted.

Figure 5. This is another type of geared winch on the market.

3. Use chains with non-rebounding tensioners

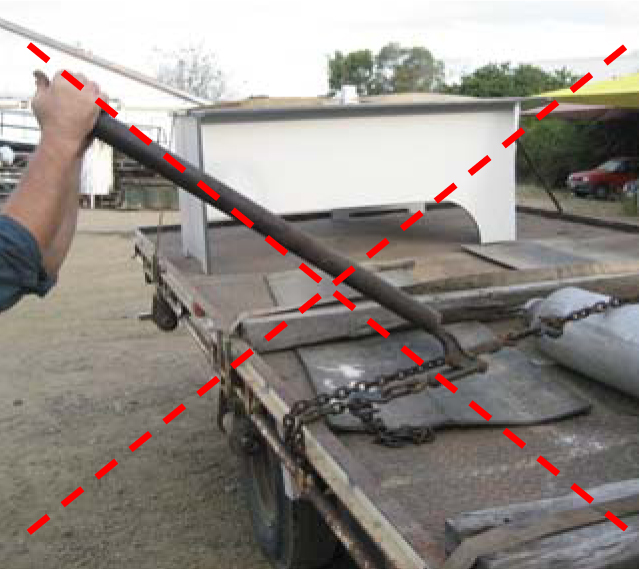

- If using chain lashings, an alternative to an over-centre lever style load binder (a dog) should be used. Many workers find they cannot get satisfactory chain tension when using a dog so they often use an extension bar to increase the tension. This practice is dangerous because the extension bar can rebound quickly during tightening and releasing and may even fly into the air. This applies to generic, manufactured extension bars, pipe handles and any other makeshift extension bar. A dog and an extension bar (see Figure 6) should not be used to tension chains when it is practicable to use an alternative.

Figure 6. An over-centre lever style load binder (a dog) with an extension (cheater bar) should not be used to tension chains when it is practicable to use an alternative.

- A turnbuckle tensioner (see Figure 7), or another type of non-rebounding tensioner (see Figures 8, 9, 10 and 11) can be used instead of a dog. Turnbuckles have no kickback and can gain very high tensions without using extension bars. Ratchet and sliding lever turnbuckles are available.

Figure 7. Two types of ratchet turnbuckle chain tensioners.

Figure 8. A type of chain tensioner.

Figure 9. A type of chain tensioner.

Figure 10. A type of chain tensioner.

Figure 11. A type of chain tensioner.

4. Control remaining risk by using administrative controls and personal protective equipment

Dogs, with or without extension bars, should not be used to tension chains unless all other ways in which to safely secure the load have been assessed and the use of a dog, with or without an extension bar, is the only practicable way to secure the load. Other ways to secure the load include the use of blocking, webbing and webbing tensioners or chains with tensioners which do not recoil when tensioning or releasing.

Whatever load securing and tensioning equipment is selected, if the risks (including from being struck and from muscular stress) are not completely controlled, the risk is to be minimised by implementing administrative controls and/or the provision and use of suitable personal protective equipment.

Administrative controls are work methods or procedures that are designed to minimise exposure to a hazard. For instance, develop procedures on how to use the equipment safely, train the workers in the procedures and use signs to remind the workers of the risks.

When using tensioners, workers should:

- wear gloves with all chain tensioners to reduce the risk of pinched hands

- position chain tensioners below shoulder height, or use a stable-standing aid when applying or releasing tensioners

- inspect and maintain tensioners regularly to ensure effectiveness and safety. A record, such as a defective vehicle report, and history of maintenance will help identify how often they need to be inspected.

Further information

This information has been taken from the Worksafe Victoria Guidance Note - Safe handling when securing loads on trucks.

View our Safely securing loads of trucks film and Safe handling when securing loads webinar.