Ammonium storage structures

Ammonium storage structures must address these requirements.*

Requirements below are referenced from Australian Standard AS4326- The storage and handling of oxidizing agents. Specific explosive regulations and relevant documents (e.g. Explosives information bulletin no. 53) must be consulted and complied with. Resources Safety and Health Queensland (RSHQ) are the lead regulatory agency for explosives in Queensland.

Design considerations

In designing ammonium nitrate storage facilities, consider the following:

- Do not store ammonium nitrate in buildings over one storey.

- Construct stores out of non-combustible materials and ensure they are compatible with the ammonium nitrate.

- Protect buildings against lightning damage. AS/NZS 1768: Lightning protection can provide guidance on lightning protection.

- Use concrete flooring that is open and without traps, pits, tunnels, or pockets where molten ammonium nitrate could flow and be confined in the event of a fire.

- Protect floors made of other materials against impregnation by ammonium nitrate.

- Use flooring that has a fall to an open drainage system that will not allow molten ammonium nitrate to become trapped or confined.

- Do not use silos for ammonium nitrate storage if the material is stored for longer than one week as this material tends to form hard cakes of material, which may be difficult to remove safely. This can lead to silo turnover during emptying if there is a hang-up on one side of hopper.

- Construct shelving systems to prevent the build-up of the ammonium nitrate or other contaminants on ledges or in corners allowing spills to be easily seen.

- Do not allow liquid to accumulate on the shelving.

- Ensure shelving/storage racks give free passage.

- Ensure buildings and structures are free from water leaks or seepage through walls, floors or roof to allow for dry storage of ammonium nitrate.

Electrical equipment

- Ensure electrical wiring and lighting in the store can withstand corrosion that may occur in regular fittings. It should have a rating of at least IP65 as per AS1939: Degrees of protection provided by enclosures for electrical equipment (IP Code).

- Keep electrical equipment where it cannot come into contact with ammonium nitrate.

- Locate or guard electrical lamps to prevent hot surfaces coming into contact with bags of ammonium nitrate.

Piles or stacks of ammonium nitrate

- Limit stacks of ammonium bags to 3 m high except where pallet racking systems are used.

- Store IBCs (bulk bags) of ammonium nitrate in stable stacks, preferably less than 3 m high.

- Maintain at least 1.2 m free air space between stacks of ammonium nitrate as well as between each stack and the walls of the building.

- Consult the manufacturer for information on the maximum allowable stack height.

- Do not store other products in the same stack with ammonium nitrate.

- Securely stack or suitably restrain containers of ammonium nitrate from falling.

Ventilation and atmospheric controls

Ensure stores are adequately ventilated using either natural or mechanical ventilations systems.

- Keep inhalation below any national exposure standard.

- The manufacturer of the ammonium nitrate may recommend humidity control.

- Do not allow the temperature of ammonium nitrate storage to exceed 55°C.

Locating storage areas

When locating ammonium nitrate storage areas, consider:

- Keeping storage areas a suitable distance from protected places where members of the public may be placed at risk (e.g. property boundaries, schools, places of worship, colleges, theatres, hospitals, age care facilities). Suitable separation distances are recommended in Table 4.2 of AS4326: The storage and handling of oxidizing agents. A store of ammonium nitrate must never be located inside a protected place.

- Locating storage areas on a floor with immediate access from outside the building.

- Keeping all vegetation, combustible materials and non-associated equipment at least 10 m away from ammonium nitrate stores.

More information about siting of ammonium nitrate storage facilities is available from:

- Resources Safety and Health Queensland's Explosives Inspectorate

- NSW Department of Planning Hazardous Industry Planning Advisory Paper No. 4 Risk criteria for land use safety planning.

Safety signs

- Sign post stores with appropriate safety signs to prohibit smoking, for instance 'Danger: no smoking'.

- Erect signs to restrict unauthorised entry.

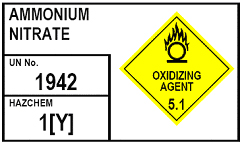

Placarding storage areas

Placarding is required where ammonium nitrate is stored in excess of the placarding quantities prescribed in schedule 11 of the Work Health and Safety Regulation 2011.

Where the placarding quantities have been exceeded an outer warning placard stating 'HAZCHEM' as shown below, must be visible from every entrance to the premises.

Information placards are required to be placed at the following locations where goods are stored in excess of the placarding quantity:

- The main point of entry into a building.

- At either the main point of entry to a room or enclosure or other area.

- Adjacent to the where the ammonium nitrate is being stored.

Information placards may take two forms:

- For package stores, the placard consists of the oxidising agent (class 5.1) label for each building, room or area where material is present in excess of the placarding quantity. The class diamonds must be at least 100 mm in diameter and not confused or obstructed by other signs or objects.

- Those for tanks and bulker bags (i.e. single bulk containers with a capacity exceeding 500 kg or litres,) need to be in the format shown below, displaying the UN number, proper shipping name, class label and HAZCHEM code.

Bulk container (tank) information placard

Packages are those containers with a capacity of less than 500 kg net mass. Any container larger than 500 kg that is regarded as a bulk container.