Gases in cylinders

Compressed gas cylinders contain gas stored under significant pressure, presenting a significant hazard in the workplace.

What are the dangers?

Hazards due to the chemical properties of gas cylinders include:

- fire or explosion from the release of flammable gases near ignition sources (e.g. acetylene or liquid petroleum gas)

- spontaneous combustion from oxidising gases (e.g. oxygen or nitrous oxide)

- exposure to toxic or corrosive gases (e.g. anhydrous ammonia)

- asphyxiation from some non-toxic, non-flammable gases by displacement of oxygen (e.g. nitrogen, carbon dioxide or argon).

Potential dangers

- Damage to a valve or regulator may cause a failure and rapid release of the gas.

- Heating of the cylinder from heat source including fire or an impact to the pressure vessel, may lead to a catastrophic rupture resulting in a rapid and large release of gas and flying shrapnel.

- An uncontrolled release of a flammable gas (e.g. LP gas, hydrogen) may lead to a fire or explosion, particularly in a confined area where potential ignition sources are present.

- If an uncontrolled release is of a toxic gas (e.g. ammonia or chlorine), workers and other persons may be at risk of a toxic exposure.

- Low boiling point, cryogenic or liquefied gases (e.g. oxygen, nitrogen) present thermal hazards where frostbite may occur with skin contact. Oxidizing gases such as oxygen have the additional hazard of increasing the propensity for things to burn and increase the intensity of a fire.

- Some gases are also denser than air (e.g. LPG, carbon dioxide). On release, these gases will tend to collect in low lying areas such as pits, depressions and basements. Depending on the chemical properties of the heavier than air gas, people working in low lying areas may be exposed to the risk of fire or explosion, asphyxiation, or exposure to toxic or corrosive gases.

- Large gas cylinders (e.g. G or F sized cylinders) can also be bulky, heavy, awkward objects that could cause severe strain and sprain injuries from inappropriate handling practices.

Safety data sheets (SDSs)

- Obtain SDSs from the supplier for each gas cylinder and keep in a register.

- Locate each SDS close to workers who may be potentially affected by the gas and ensure it is readily accessible. Also ensure that emergency responders have access to this information if required during an incident.

- Read the SDS to identify:

- chemical and physical hazards from each gas cylinder

- appropriate safe storage and handling practices

- the need for additional control measures

- first aid measures

- firefighting and emergency information.

- Conduct and record a risk assessment to identify hazards and the need for any additional control measures.

- Provide workers with information, training and effective supervision, about the hazards from gas cylinders, safe storage and handling information and what to do in an emergency.

- Document procedures to inform workers about how to store and handle gas cylinders safely.

Safe handling practices

- Store cylinders in the upright position. Some gases (e.g. LPG and acetylene) contain a gaseous and liquid phase. Some flammable gas cylinders contain a pressure relief valve that must be in contact with the vapour phase if the cylinder is to function properly during an emergency.

- Ensure cylinders are prevented from falling or being knocked over by securing them using a racking system or using a non abrasive, coated chain that will not scratch the cylinder markings and paint work.

- Avoid knocking cylinders about. Prevent damage to cylinders caused by impact from other objects (e.g. crashing into other cylinders). Some cylinders (e.g. acetylene) may react violently after being excessively shaken, heated, or knocked.

- Do not use cylinders as rollers to move other objects.

- When moving cylinders, avoid rolling them. Ensure that an appropriate mechanical handling device (e.g. cylinder trolley with a restraining strap) is used. More information on manual handling of gas cylinders is available in the Victorian Government publication, Delivering large gas cylinders - A guide to manual handling (non-Queensland Government link)

- Wear eye protection, safety shoes and gloves in gas cylinder storage and handling areas.

Storage and ventilation

Gas cylinders should be stored outdoors, preferably in a secure, cage that's protected from sunlight. Storage indoors is not recommended unless the building has been designed for that purpose with appropriate fire-rated walls and ventilation.

Some general principles apply:

- Do not store gas cylinders in areas or structures constructed of combustible materials.

- Locate gas stores on the ground floor away from other dangerous goods (e.g. Class 3, 4, 5, 6.1, 7, 8 or 9, etc.) and combustible liquids (e.g. diesel fuel) stores by at least 5 m or more.

- Avoid storing below ground level especially if flammable, toxic or asphyxiant gases are present.

- Store heavier than air gases with caution to avoid storing where these gases can collect in low lying areas.

- Avoid storing gas cylinders in significant quantities near to or inside protected places where members of the public may assemble (e.g. places of worship, theatres, age care facilities, schools, hospitals, property boundaries).

Where gas cylinders are stored indoors:

- Store gas cylinders in well ventilated areas to prevent build up of escaped gases.

- Store gases outside in a cage where possible.

- Where gases are stored inside a building, a mechanical ventilation system may be required if the natural ventilation is inadequate. Expert advice should be obtained if unsure.

- Design the mechanical ventilation system to capture escaped gases, not ignite flammable gases. Ensure workers are not placed at risk of asphyxiation, or exposed to gases above the relevant National Exposure Standard (NES). National standards are those stated in the Workplace Exposure Standard (WES) as specified in Workplace exposure standards for airborne contaminants published by Safe Work Australia.

For LPG or other workplaces where flammable gases are the dominant gas present, contact the Department of Natural Resources and Mines' Petroleum and Gas Inspectorate regarding obligations under the Petroleum and Gas (Production and Safety) Act 2004.

Heat and ignition sources

- Store cylinders in cool areas away from sources of radiant heat (e.g. boilers, hot surfaces, and internal combustion engines). Where possible, store cylinders in the shade to avoid exposing cylinders to direct sunlight.

- Do not store flammable gas cylinders near sources of ignition such as naked lights or cigarette smoking.

- Where flammable gas is used, erect appropriate signs stating 'No smoking', 'No naked lights' to prevent ignition sources in these areas.

- Wherever flammable gases are used, stored and handled, fire and explosion risks must be safely managed.

Segregate incompatible gases and hazardous chemicals

Store gas cylinders separately from other hazardous chemicals by at least 5 m or by using appropriate fire-rated barriers as:

- corrosive liquids can damage gas cylinders on contact

- flammable liquids can spread a fire across a workplace floor and allow flames to come into contact with gas cylinders

- other hazardous chemicals may also be adversely affected by gas cylinders in an emergency.

Segregation of incompatible goods also allows fire fighters to safely use appropriate firefighting media for each type of goods present.

Gas cylinders must also be segregated from other incompatible gases by at least 3 m or more. The following is recommended:

- Store class 2.3 Toxic gas and corrosive gases (those with a subsidiary risk of class 8 Corrosive) away from all other gas cylinders.

- Segregate class 2.1 Flammable gas during storage from all oxidising gases.

Mutually compatible gases (e.g. Class 2.2, without subsidiary risk) may be used between incompatible gases.

Housekeeping

- Do not store objects on top of gas cylinders.

- Store full and empty cylinders separately, in clearly marked areas.

- Rotate stock, ensuring a first-in-first-out process.

- Ensure gas cylinders are stored at least 3 m away from combustible materials and debris (e.g. timber, cardboard, packaging materials).

- Do not locate gas cylinders where they may block stairs, exits, ladders or walkways.

- Keep an up-to-date and accurate inventory.

- Keep inventory quantities as low as possible.

Emergency planning

Emergency plans must be developed wherever hazardous chemicals (including gases) are used, stored and handled. Possible hazards, incidents and emergency situations should be considered, including:

- likely types of emergencies (e.g. fires, gas leaks for each type of gas, explosion)

- the adequacy of firefighting systems

- access to and from the site

- a safe evacuation area

- the need to notify neighbours

- providing and testing alarms

- carrying out regular emergency drills.

Refer to the general guidance on emergency planning for hazardous chemicals.

If gas products classified as hazardous chemicals are used, stored or handled in excess of the prescribed manifest quantities in column 4 of schedule 12 of the Work Health and Safety Regulation 2011, an emergency services manifest is required at the workplace. The manifest must contain an up-to-date inventory of hazardous chemicals used, stored and handled at the workplace, including the quantity and location of each gas storage area. Schedule 12 of prescribes the information to be included in the manifest and site plan. The manifest and site plan should be kept in a red weatherproof container at the main entrance to the workplace.

Notification

If gas products classified as hazardous chemicals are used, stored or handled in excess of the manifest quantity, then notify Workplace Health and Safety Queensland.

Placarding storage areas

Where gases are stored in excess of the prescribed placarding quantities shown in column 4 of schedule 11 in the Work Health and Safety Regulation, placarding must be erected at the following locations:

- the main point of entry into a building

- at either the main point of entry to a room or enclosure or other area

- adjacent to the where the gas cylinders are being stored.

Where the prescribed placarding quantities are exceeded at a workplace, an outer warning placard stating 'HAZCHEM' must be visible from every entrance to the premises.

Information placards may take two forms:

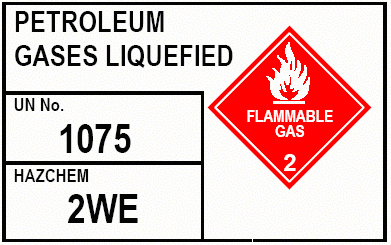

- Those for tanks (bulk gas containers that have a water capacity* of 500 L or more) need to be in the format shown in Figure 1 displaying, the proper shipping name, UN number, class diamond label and HAZCHEM Code.

- For package stores, the placard consists of the dangerous goods class label (i.e. 'diamond') for each class of gas stored in excess of the placarding quantity. The class diamonds must be at least 100 mm in diameter and not confused or obstructed by other signs or objects. (Note: Packages are those cylinders that are less than 500 litres water capacity*). Examples of the class labels for gas stores are shown in Figure 2.

Figure 1: Tank information placard (i.e. bulk containers)

Figure 2: Dangerous goods class labels from the ADG Code for gases

* Water capacity refers to the volume of water the container would hold when full, expressed in litres.

More information

More information on managing hazardous chemical risks is available in Managing risks of hazardous chemicals in the workplace Code of Practice 2021 (PDF, 1.21 MB).

Specific guidance on the safe storage and handling of gases in cylinders is available from various Australian standards related to gases in cylinders including: