Welding

Welding is a hazardous activity that can expose workers to many dangers. Find out how to manage these risks.

What is welding?

Welding is a fabrication process that permanently joins two materials, usually metals, by enough heat to melt the material being joined. Sometimes pressure, or a combination of heat and pressure, can be used to weld materials together. Welding is used across industry for construction, maintenance, and repair work, as well as to manufacture equipment, machinery, and tools.

What are the risks of welding?

You must have controls in place to eliminate or manage welding risks, as many can cause immediate and life-threatening danger to workers.

- Electrical equipment that is in bad condition, poorly maintained or has damaged insulation, can expose workers to the risk of electric shock.

- Poorly maintained personal protective equipment (PPE) can result in burns and vision and hearing damage.

- Sparks, excessive heat or radiation may result in burns, welding flashes or fire.

- Heating metals above boiling point also generates welding fumes.

Workers could inhale fume gases and vapours from:

- the metal being welded

- coatings such as paint or zinc on the material being welded

- heating chemical residues.

Containers that have had flammable or combustible substances in them are a fire and explosion hazard while being welded. Welding these containers must be supervised by a suitably qualified person. Make sure you check all containers before you begin work.

Containers that have contained:

- flammable substances like unleaded petrol and acetone may be marked with a flame symbol

- combustible substances, such as diesel fuel, greases, tar, engine oils, linseed oil or tallow, might not be marked with a flame symbol because they are not normally flammable at normal temperatures and pressures. However, when they’re exposed to the extremely high temperatures and pressures of welding they may create enough vapour to cause an explosion, particularly inside a sealed drum.

Check AS 1674.1 (1997) Safety in welding and allied processes, Part 1: Fire precautions for guidance on managing and supervising these hazards

There’s a risk of workers inhaling toxic gases, fumes or getting an electric shock if they’re welding in:

- a hazardous area

- a poorly ventilated or confined space

- a wet environment.

Welding is hot work that can have fire and explosion risks.

Less experienced welders, or those unfamiliar with the tools, may risk injuries from poor work practices.

Specific welding hazards and their risks

Hazards specific to welding include the following.

Welding fumes are complex mixtures of metallic oxides, silicates and fluorides and some can cause cancer and other ill health effects.

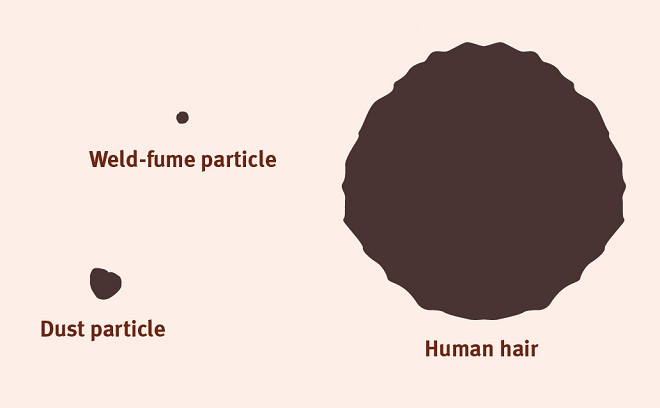

Welding fumes form when metal heats above its boiling point. As the metal cools it condenses into particles so small they can easily be breathed into the lungs.

Welding fumes can contain particles from the electrode and the material being welded. Any coatings or residues left on metals can also break down during welding and cause toxic fumes.

Some welding fumes are easy to see, but many are too small to be seen with the naked eye.

Graphic: Relative size of welding-fume particle

Your exposure to welding fumes can be affected by the:

- type of welding process, for example flame gouging, higher-current metal inert gas shielded welding—particularly on stainless steel, aluminium, copper, nickel and their alloys, mechanised flame cutting, oxygen arc cutting and gouging, flux-cored electrode welding

- composition of welding rod, for example, cadmium-containing solder, chromium, nickel, vanadium, manganese and iron

- filler metals and base metal used, for example, stainless steel, aluminium

- types of coatings present, for example, work on metallic coatings such as cadmium or zinc plating, lead, chromium, manganese, cobalt and/or nickel hard surfaces, cadmium plating, paints or solvents, some plastic coatings, zinc on galvanised steel

- location of the work, for example, open area or confined space

- type of ventilation controls, for example, forced dilution or local exhaust ventilation

- work practices of welder, for example, removing coatings, cleaning surfaces, staying upwind when welding in open or outdoors.

Gas welding usually produces less fume than electric welding, except for processes involving heavy cutting and gouging.

Some welding risks may be less obvious, with health effects showing later. For example, there are both short-term and long-term effects to the lungs caused by exposure to toxic gases, fumes and airborne contaminants when welding.

Health effects

Acute or prolonged exposure to welding fumes may result in:

- siderosis caused by iron oxide

- occupational asthma caused by stainless steel welding, chromium, nickel

- metal fume fever caused by zinc oxide, magnesium oxide, copper, aluminium

- nervous system disorders caused by manganese

- respiratory tract irritation caused by aluminium, cadmium oxides, copper, molybdenum, nickel, vanadium

- eye irritation caused by vanadium, nickel, molybdenum, fluorides, copper

- kidney damage caused by cadmium oxide, fluorides, lead

- cancer caused by cadmium oxide, nickel, chromium (VI), beryllium

- dermatitis, eczema caused by nickel, chromium (VI)

- lung damage caused by cadmium oxide, fluorides, vanadium

- bone and joint problems caused by fluorides

- lead poisoning caused by batteries, materials contaminated with lead or coated with lead-based paints.

Phil’s story is a first-hand account of how breathing in welding fumes over a long period of time without adequate controls caused him to suffer occupational asthma, a permanent respiratory condition.

Gases are sometimes used when you’re welding or cutting. Gases or vapours might also be produced when coatings or chemical residues are not removed from metals before you begin welding. These gases and vapours can be hazardous.

Gases used in the welding or cutting process:

- shielding gases—carbon dioxide, argon, helium

- fuel gases—acetylene, propane, butane

- oxygen used with fuel and some shielding gas mixes.

Gases and vapours produced from the welding or cutting process:

- carbon dioxide from decomposition of fluxes

- carbon monoxide from the breakdown of carbon dioxide shielding gases in arc welding

- ozone from the interaction of electric arc with atmospheric oxygen

- nitrogen oxides from heating of atmospheric oxygen and nitrogen

- hydrogen chloride and phosgene produced by the reaction between ultraviolet light and vapours from chlorinated hydrocarbon degreasing solvents, for example trichloroethylene.

Gases and vapours produced from thermal breakdown of coatings:

- hydrogen cyanide, formaldehyde, carbon dioxide, carbon monoxide, oxides of nitrogen and isocyanate vapours from heating of polyurethane coatings

- carbon monoxide and carbon dioxide from heating epoxy coatings

- phosphine gas when phosphate rust-inhibiting paints coatings are heated during welding.

Health effects

The health effects of prolonged exposure to welding gases and vapours include:

- asphyxia caused by carbon monoxide, oxygen deficiency

- lung damage caused by ozone, nitrogen oxide

- headaches and dizziness caused by carbon monoxide, ozone

- kidney damage caused by phosphine, hydrogen fluoride

- bone and liver damage caused by hydrogen fluoride

- hearing loss caused by carbon monoxide

- respiratory tract and/or nose irritation caused by hydrogen fluoride, nitrogen oxides, phosphine, aldehydes, isocyanates, phosgene

- eye irritation caused by hydrogen fluoride, nitrogen oxides, ozone, phosphine, aldehydes, isocyanates, phosgene

- sensitisation caused by isocyanates

- polymer fume fever caused by fluoropolymers.

Some activities outside of work, like cigarette smoking, can worsen the adverse health effects or respiratory hazards related to welding.

See below for information about the controls required protect against welding gases and organic vapours.

Ozone is formed in the welding arc when the electric arc interacts with atmospheric oxygen and can be hazardous when you breathe it in.

Health effects

The health effects of ozone will depend on the amount you breathe in and can include:

- headaches and dry eyes

- irritation of the upper airways causing coughing and tightness in the chest

- at very high levels, damage to the lungs.

Electric arc and laser welding emit ultraviolet (UV), visible light and infra-red radiation. Gas welding emits visible light and infra-red radiation. Radiation from welding may cause injury to both the eyes and skin.

Some welding electrodes contain low-level radioactive material, for example, red-tipped TIG electrodes, 2% thoriated, contain thorium oxide. You should use appropriate PPE and dust-collection systems when grinding thoriated welding electrodes to prevent inhaling radioactive dust.

The effects and type of radiation on the body will depend on:

- the type of welding (electric arc, laser or gas welding)

- the intensity of the radiation

- how far you are away from the welding activity

- how long you are exposed to the radiation.

Workers directly involved in the welding process are at greatest risk, however other workers in the workplace or passers-by could also be exposed to radiation.

Health effects

Eye disorders can occur from exposure to all forms of welding radiation and may include:

- damage to the cornea caused by UV and infra-red radiation

- cataracts caused by UV and infra-red radiation

- blindness caused by UV and infra-red radiation

- arc eye or welders flash, which is a painful inflammation of the cornea which generally repairs itself over one to two days caused by UV radiation

- temporary blindness and eye fatigue caused by visible light.

Skin damage can occur from exposure to UV radiation and includes:

- burns to unprotected skin

- skin cancers caused by long-term exposure to UV radiation.

See below for advice on controls that can protect workers from UV and infra-red radiation.

New classification for welding fumes and UV radiation

Welding fumes and UV radiation emitted during welding are categorised as Group 1 carcinogens (carcinogenic to humans) according to the International Agency for Research on Cancer (IARC) in 2019. You can read more about the new IARC classification.

How do I manage the risks?

Workers and management can work together to reduce the risks of hazards at work. A safe place of work benefits everyone. Access more information about how you can create safe work.

The Welding processes Code of Practice 2021 (PDF, 0.95 MB) outlines requirements for specific situations where welding is done, such as working in confined spaces (PDF, 1.43 MB)

For workers

As a worker, you must take reasonable care for your own health and safety and make sure your work doesn’t impact on the health and safety of others. You must comply with any reasonable instructions given relating to risk control measures and emergency procedures. You should also make sure you work according to any training or information that’s been provided to you.

Welding should only be done by competent and skilled workers. You should know the right way to do the work and how to prevent harming yourself and others.

For businesses

If you're an employer or person conducting a business or undertaking (PCBU), you have a duty to manage risks, as outlined in the Work Health and Safety Act 2011 (WHS Act). Use the practical advice in the How to manage work health and safety risks Code of Practice 2021 (PDF, 0.65 MB).

Following the four-step risk management process below will help you meet your responsibilities.

Four steps to manage the risk

The first step in managing welding risks is to identify all hazards that can cause harm.

You can identify potential hazards by:

- conducting a workplace walk through assessment to observe the work being done and to talk to workers about how they are doing the work

- inspecting the materials and equipment that will be used during the welding process

- reading product labels, safety data sheets (SDSs) and manufacturer instruction manuals

- talking to manufacturers, suppliers, industry associations, and health and safety specialists

- reviewing incident reports.

A risk assessment may help:

- identify which workers are at risk of exposure

- determine what sources and processes are causing that risk

- identify if and what kind of control measures should be implemented

- check the effectiveness of existing control measures.

When you’re assessing risks from welding, take into account:

- properties of the materials being welded

- the surface coating of the items being welded

- chemicals that are/were contained within the item being welded

- the condition of the welding equipment

- conditions under which welding is carried out

- the environment in and around the item being welded

- skills, competence and experience of the welder.

You should review the Welding processes Code of Practice 2021 (PDF, 0.95 MB) for risk assessment guidance for specific welding hazards.

The Welding processes Code of Practice 2021 (PDF, 0.95 MB) recommends control measures your workplace can put in place. Control measures can include:

- isolating fuel sources from ignition sources

- ventilation including natural ventilation, forced dilution ventilation and local exhaust ventilation

- installing non-flammable screens and partitions

- using signs to warn and prevent others from entering the work area

- providing PPE such as filter shades for goggles, face shields, gloves and other protective clothing to cover exposed skin

- provide respiratory protective equipment (RPE) such as air-purifying respirators or supplied-air respirators which can be incorporated into the welding helmet.

- ensuring that workers drink cool water and take regular, scheduled rest breaks.

You should provide workers who carry out welding with information and training about:

- the proper use, storage and maintenance of personal protective equipment (PPE)

- how to work safely in hazardous environments, such as confined spaces, hazardous atmospheres and hazardous areas

- how to safely control any fire, explosion or toxic gas hazards if welding on containers that have contained chemicals

- first aid and emergency procedures

- how to access safety data sheets (SDS) for hazardous chemicals

- the nature of and reasons for any health monitoring if required.

See below for specific risk controls.

You should regularly review welding risk controls to make sure they are effective. You can read more about when work health and safety laws require you to review your risk controls.

Health monitoring detects changes in a worker’s health because of exposure to certain substances. The Welding processes code of practice 2021 outlines when and how you must provide health monitoring.

Specific risk controls

Some controls are more effective than others. The Welding processes code of practice 2021 outlines specific ways to control risks according to the hierarchy of risk controls.

Eliminate the risk

Eliminating a risk is the most effective way of keeping your workers safe.

You can eliminate welding risks by designing fabrications to include pre-cast components or extruded shapes that don’t need welding.

You can reduce risks by:

- removing coatings or paint from surfaces before starting welding, however

- don’t grind coatings because the grinding dust could be toxic

- use wet slurry vacuum removal techniques or stripping products to remove coatings

- make sure to remove any chemical residues before you start welding

- using water-based cleaners or high-flashpoint solvents instead of chlorinated solvents for cleaning metals prior to welding.

Choose a welding technique and consumables that makes less fume and/or UV radiation.

You can read more about the amount of welding fume produced by different types of welding on the Cancer Council website.

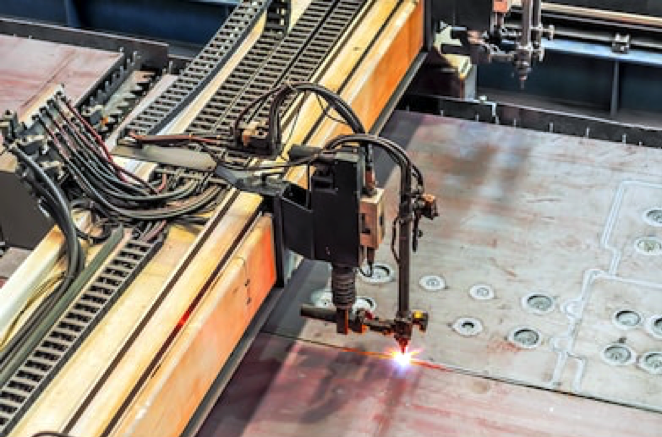

Use automated welding systems and process enclosures to remove the worker and/or permit the operator to stay clear of the welding plume and exposure to radiation.

Photograph: Automated welding system

Use jigs to turn material being welded so workers do not have to stand directly over the welding plume.

Control the exposure

If you can’t eliminate the hazard and associated risks, you should minimise the risks using the following controls.

Ventilation can reduce exposure to fumes and other airborne contaminants. A combination of local exhaust and forced dilution ventilation is best practice. Local exhaust ventilation (LEV) systems remove gases, fumes, dusts and vapours at the source before they can mix with the room air.

You should use natural ventilation, such as open windows or doors, only for general comfort. Natural ventilation doesn’t reliably dilute or disperse airborne contaminants in the work area.

The following are examples of local exhaust ventilation systems suitable for welding operations include.

Side-draft or down-draft tables and benches or partially or completely enclosed booths

These draw away welding fumes and gases away from where they can be breathed in by the worker. They need to have sufficient air speed to keep the welding fumes and gases from rising into the breathing zone of the worker. Ensure work pieces don’t cover too much of the ducting or the exhaust effect will be lost.

Portable hoods

Portable hoods attached to flexible ducts placed as close as practical to the work will draw welding fumes and gases away from the worker’s breathing zone. The optimal location for the hood is about 1 duct diameter from the arc. They should have a minimum air velocity of 0.5 m/s across the welding arc.

Photograph: A worker using a portable hood to draw welding fume away from their breathing zone

Ensure welding plumes do not enter the welder’s breathing zone by positioning LEV hoods correctly.

On-torch extraction systems

On-torch extraction systems remove fumes and gases very close to the source. They can be very effective on flat and vertical surfaces, in corners and around flanges. Approximately 90 per cent of welding fume is captured when using on-torch extraction systems.

Watch a video on the effectiveness of on-torch extraction.

Using fans or leaving doors and windows open is not as effective as using LEV to control fumes.

Prevent other workers breathing in welding fumes and gases by separating welding from other workplace activities. Use non-flammable welding screens and partitions to protect other workers from radiation hazards.

- Arrange work so hot gases and fumes do not rise into the worker’s face.

- Ensure you use properly sized welds as ‘over welding’ will increase the amount of fume.

- Use the lowest voltage you can for whatever welding process you’re doing.

- Use warning signs when welding is happening.

- Don’t allow entry into the work area without safeguards like PPE, if welding is being done.

Train workers who weld in:

- welding hazards

- the risks associated with exposure to welding fume, gases, ozone and ultraviolet radiation

- how to use the controls available in the workplace to prevent welding fumes and gases becoming airborne and prevent exposure to radiation

- how to use, wear and store any PPE or RPE

- how to work safely in hazardous environments like confined spaces

- first aid and emergency procedures

- how to access safety data sheets (SDS) for hazardous chemicals

- the nature of, and reasons for, any health monitoring if it is required.

Personal protective equipment

You should not rely on personal protective equipment (PPE) or respiratory protective equipment (RPE) alone to protect workers from inhalation and radiation risks.

A welding helmet alone is not effective at keeping you safe from fumes, gases and vapours and may cause contaminants to be trapped within the helmet.

PPE to protect workers from UV radiation and burns includes:

- fire/flame resistant clothing and aprons such as rawhide operator’s jackets, cotton heat vests and long-cuff welding gloves/gauntlets

- tightly woven work material long pants and long-sleeved shirts buttoned up around the neck and cuffs will keep UV radiation reaching the skin.

- fire-resistant skull caps or balaclava hoods to protect the scalp and head

- insulated gloves

- helmets, hand shields and goggles fitted with protective filter shades suitable to the type of welding being undertaken. A tight-fitting opaque welder’s helmet provides protection to the face from UV radiation.

- high top rubber soled boots designed for welding tasks, fully laced and fire-resistant boot protectors or spats strapped around the pant legs and boot tops to prevent sparks from bouncing into the top of the boots to prevent burns.

Welding work requires specific RPE to prevent breathing in fumes, gases and vapours.

Where there is a safe level of oxygen:

- use a respirator filter at least rated to P2 to protect against fumes

- use an organic vapour filter such as activated carbon or charcoal where ozone or organic vapours are present.

Powered air-purifying respirators (PARPs) supply filtered air to the workers breathing zone and can be incorporated into welding helmets. Because filtered air is constantly flowing into the headpiece under pressure, leakage of contaminants into the helmet is greatly reduced.

Photograph: Worker welding wearing an air-fed welding helmet

Supplied-air respirators must be used where:

- there is an oxygen deficient environment, such as a confined space

or

- the type or extent of atmospheric contamination remains unknown.

You may also need a supplied-air respirator to protect against some gases and vapours that can’t be effectively filtered, such as argon or carbon monoxide when working in a confined space.

Find out more about selecting and using RPE .

The committee was established to ensure there is an ongoing consultative forum for injured workers and families affected by a workplace death, illness or serious incident. Read more about the committee.

Standards and compliance

The following Standards provide additional guidance on how to manage risks associated with welding.

- AS1674.1-1997: Safety in welding and allied processes - Fire precautions

- AS4839-2001: The safe use of portable and mobile oxy-fuel gas systems for welding, cutting, heating and allied processes

- AS/NZS1338.1: Filters for eye protectors – Filters for protection against radiation generated in welding and allied operations

- AS/NZS1337.1: Personal eye protection – Eye and face protectors for occupational applications

- AS/NZS1801: Occupational protective helmets

- AS/NZS 1715: Selection, use and maintenance of respiratory protective equipment

- AS/NZS1716: Respiratory protective equipment

Code of practice

Carefully read all relevant codes of practice to make sure your business is complying with the health and safety duties in the WHS Act and Electrical Safety Act.

- Welding processes Code of Practice 2021 (PDF, 0.95 MB)

- Electrical Safety code of practice – electrical equipment rural industry 2020 (PDF, 0.58 MB)

- Demolition work Code of Practice 2021 (PDF, 0.66 MB)

- Managing the risk of falls at workplaces Code of Practice 2021 (PDF, 3.9 MB)

- Confined spaces Code of Practice 2021 (PDF, 1.43 MB)

- Preparation of safety data sheets for hazardous chemicals Code of Practice 2021 (PDF, 1.03 MB)

Related links

- Hot work and welding near explosive substances

- Explosive conditions: grinding, cutting and welding (including pre-heating) from the inside or outside of confined spaces

- Manual task case study: Using an oxy cutting/welding torch on rotators – Monadelphous Engineering (PDF, 0.12 MB)

- Airborne contaminants

- Electrical risks

- Fire and explosion (from hazardous atmospheres and hazardous areas)

- Burns and exposure to heat

- Compressed and liquefied gases

- Noise

- Lead

- Confined spaces

- Work at heights

- Breathe Freely in welding

- Cancer Council - welding

- Weld Australia – access two free online Welder Safety Training Courses: one for welders and the other for welding engineers and supervisors