Phosphine gas

Phosphine is used to kill insects, mice and rats in grain and seed storage and it occurs as a by-product of some industrial manufacturing processes for chemicals, semi-conductors, welding and metal alloys.

It is dangerous to breathe in phosphine gas and you can become ill or die depending on the amount. Find out more about your legal obligations to manage phosphine gas exposure and how to keep workers safe.

What is phosphine gas?

Phosphine is a highly toxic respirable poison. On farms it forms when fumigation tablets containing aluminium phosphide react with moisture in the air. When you breathe in the gas, it reacts further with the moisture in your lungs to make an acid.

Phosphine is a colourless, flammable gas with no odour in its purest form. Sometimes it may smell of garlic or rotting fish from contaminants, but do not use smell to test for phosphine. It is heavier than air so hazardous concentrations develop quickly in poorly ventilated, enclosed or low-lying areas. Phosphine can self-ignite and explode.

What are the risks of phosphine gas?

Phosphine is easily breathed in. When absorbed through your lungs it affects how your body accesses and uses oxygen. In small amounts it can cause:

- headaches

- respiratory problems including coughing, chest pain or tightness

- double vision, dizziness, headache, chills and confusion

- fatigue, weakness

- gut pain, nausea, vomiting and diarrhoea.

If you are exposed to large amounts of phosphine, symptoms can be delayed for several days. High amounts can cause:

- damage to your kidneys, liver and heart

- pulmonary oedema

- convulsions

- death.

Long term, repeated exposure to phosphine may cause:

- anaemia

- bronchitis

- gastrointestinal disorders

- speech and motor disturbances

- weakness

- weight loss

- spontaneous fractures

- swelling to your jaw, tooth ache and jawbone necrosis (never open tablet packets with your teeth).

Workplace exposure standard

The workplace exposure standard (WES) for phosphine is:

- 0.3ppm (0.42 mg/m3) (8-hour TWA*)

- 1ppm (1.4 mg/m3) (STEL**)

*8-hour time-weighted average (TWA) is the maximum average airborne concentration of a substance when calculated over an eight-hour working day for a five-day working week.

**Short term exposure limit (STEL) means the time-weighted average maximum airborne concentration of a substance calculated over a 15-minute period.

Learn more about airborne contaminants.

How do I manage the risks?

Workers and managers can work together to reduce the risks of hazards at work.

Follow the safety instructions on any product containing phosphides.

For workers

As a worker, you have a responsibility to take reasonable care of your own health and safety and make sure that your work doesn’t have a negative impact on the health and safety of others.

Read the label on fumigants and follow the safety instructions.

Never check for the presence of phosphine based on smell.

For businesses

For employers or persons conducting a business or undertaking (PCBU), it’s your duty to manage phosphine gas risks, as outlined in the Work Health and Safety Act 2011.

Following the four-step risk management process below will help your business meet its responsibilities under work health and safety laws. You can also use the practical advice in the Managing risks of hazardous chemicals in the workplace Code of Practice 2021 (PDF, 1.21 MB).

Four steps to manage risk

Any industrial process that generates phosphine gas and any fumigation product that uses phosphides poses serious risks, including:

- explosion

- illness

- death.

Use questions like these to assess the risk:

- Where and when do we use or generate phosphides?

- Does our business measure and track exposure?

- Do we check for very high humidity before using it?

- Who is involved?

- Who is nearby or downwind?

- Who is the next person to use that space?

- What training do we provide our staff and when was that last refreshed?

- Are we advising the transport company that there are fumigants on the load?

- Do we give the product enough time to stand?

- Is it leaking out of silos or truck beds?

- Do we use phosphine to control rabbits?

- How are we cleaning that area and equipment?

- Is it being stored safely and securely?

- What first aid response do we have ready for an incident?

Use other information including records from workers’ compensation claims, incidents or reports. Use shared industry knowledge. Talk to your workers for their feedback and experience. Review the safety data sheet for phosphate products (available from the company who made it or the importer/supplier) and phosphine gas and evaluate your business against its information.

For each of these things work out:

- the severity of harm it could cause (from illness to serious injury or death)

- how likely that harm is to occur (from certain to unlikely or rare)

- what controls are already in place to reduce the risk of harm

- how urgently additional action needs to be taken.

The level of risk you assess for each part of your process in using phosphine will depend on all these factors.

If you aren’t certain about completing this or just want professional advice you can hire an occupational hygienist. You can find one using this list of certified consultants.

A control is any measure that reduces a risk. Sometimes a single control might be enough to eliminate a risk, like removing a tripping hazard from the work environment. Other risks, like poison gas need several control measures.

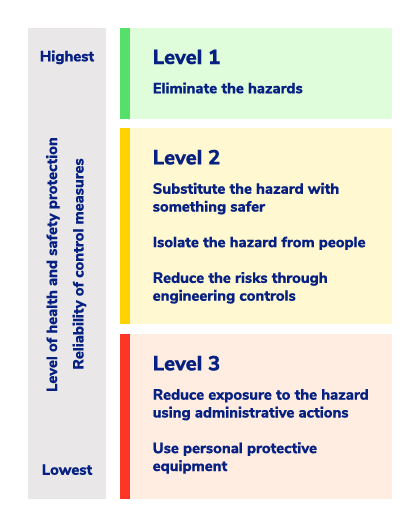

Prioritise the controls that either remove the hazard or reduce the risk most effectively. Use the hierarchy of controls to understand the types of controls you can put in place and how effective they will be. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. Eliminate the risks as much as possible through good work design.

Include your workers in any decisions about risk control. Their experience will help you choose control measures that work on paper and in practice.

Here are some controls you can use.

Level 1 - eliminate

Use fumigation processes that produce less hazardous chemicals, e.g. carbon dioxide, nitrogen.

Level 2 – substitute, isolate, reduce

- Use mechanical tools (drones, claws etc) to put tablets into storage.

- Remove rust proofing compounds from steel prior to welding.

- Prevent leaks.

- Restrict access (barriers, signage, locks).

- Comply to standing times (withholding or re-entry times) that are on the product label.

- Never fumigate grain in transit – it puts drivers and transport workers at risk.

- Give full ventilation/airing out times before cleaning.

- Use real time monitors (with alarms) to detect phosphine.

- Use good practices (for example, open canisters away from you and outdoors).

Level 3 – administrative acts and personal protective equipment (PPE)

- A full-face filter respirator or self-contained breathing apparatus should be worn where airborne concentrations may exceed 0.3 ppm.

- The filter must be approved for phosphine and suitable for short-term exposure only (type B for inorganic gases).

- The filter should be immediately discarded and destroyed if there is any hint of phosphine odour inside the face-piece. Use a life of one hour for filters, at usual exposure levels of operators in routine testing procedures before disposal/replacement.

- Self-contained breathing apparatus should be used for operations, such as breakdowns or emergencies, when longer exposures at higher concentrations may occur.

- Facial hair will prevent an adequate seal of the mask against the skin.

Other:

- Wear impervious gloves (e.g. PVC) when dispensing pellets, tablets or bag chains by hand to prevent contact between the chemical and the moisture in the air or in your skin.

- Provide inductions and training to workers.

- Use clear signage.

- Communicate clearly with your supply chain and transport companies about phosphine use.

Risk management is an ongoing process. You should check regularly to make sure the control measures are working and that staff are using them properly. Review training and work processes. If you find problems, go through the steps again, review the information and decide whether you need new controls.

You must review controls:

- when you become aware that a control measure is not working effectively

- if there is an incident or near miss

- before a change that might create a new risk

- when you find a new hazard or risk

- when your workers tell you that a review is needed

- after a health and safety representative requests a review.

You can find a list to help you find any issues in the How to manage work health and safety risks Code of Practice 2021 (PDF, 0.65 MB) .

Standards and compliance

- The Hazardous Chemicals Information System (HCIS) provides more information on workplace exposure standards.

- Pest management, including commercial fumigation, is regulated under the Pest Management Act 2001 and the Pest Management Regulation 2003.

Codes of practice

- Managing risks of hazardous chemicals in the workplace Code of Practice 2021 (PDF, 1.21 MB)

- How to manage work health and safety risks Code of Practice 2021 (PDF, 0.65 MB)

Related links

- Keeping good records of chemicals you use on the farm

- Videos by the Grains Research & Development Corporation

- Chemical pest animal control methods

- Advice on the effects of exposure to hazardous chemicals, contact the Poisons Information Centre

- Australian Institute for Occupational Hygienists list of certified consultants