Buckner Printing - a manual task case study

Buckner Printing is a printing company based in Brisbane employing 38 workers.

Background

During the medium size business initiative (MSBI), Workplace Health and Safety Queensland (WHSQ) identified the task of manually moving a paper cylinder onto a dispatch pallet as a potentially hazardous manual task during a walk around inspection of the business.

A WHSQ inspector and safety officer watched a worker perform the task in order to determine if workers were at risk of injury.

The task

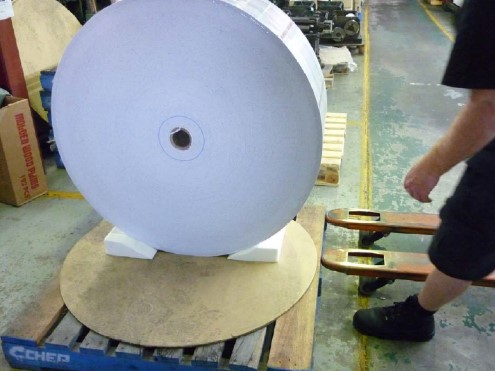

A large cylinder of printed paper, weighing 360 kg, is required to be manually moved about 10 metres from the printing machine to the storage area for dispatch. The paper cylinder comes off the machine onto the floor in an upright position.

Paper cylinder comes off printing machine in an upright position. This cylinder weighs 360 kg

The worker pivots the paper cylinder so it faces the direction of travel, then exerts a large amount of force to obtain enough speed and momentum to roll the paper up a small ramp that leads to the dispatch pallet, positioned next to an access way.

Worker spins cylinder around to face direction of travel. Smooth floor surface assists with this movement.

A big effort (forceful exertion) is needed to gather enough speed and momentum over 10 metres to manually roll the cylinder up the ramp onto the dispatch pallet.

There was no standard operating procedure or risk assessment completed for this task.

Risk factors

The following risk factors were observed by the WHSQ inspector:

- forceful exertions – the worker had to put a lot of effort into pushing the paper cylinder to gain enough speed and momentum to roll it up the ramp onto the dispatch pallet

- being hit - if the worker lost control of the heavy paper cylinder there was a risk of the worker and others being hit by the paper cylinder out of control.

Action taken

The WHSQ inspector identified that the task was hazardous and that the risks had not been controlled. The inspector discussed the task and risk factor issues as well as possible controls with the safety officer.

The inspector issued an improvement notice and the workplace was given one month to comply.

Workplace solution

The workplace safety officer later contacted the inspector to discuss potential control measures. In order to assist the safety officer to develop suitable controls, the inspector advised the safety officer to talk to the workers who do this task and collectively come up with an alternative process.

Using a pallet jack to move the heavy paper cylinders.

Following consultation with the workers, the business developed a safe operating procedure by eliminating the need for a worker to manually roll the paper cylinder up the ramp onto the dispatch pallet. The method of handling was redesigned by:

- using a pallet jack (photo 4) so that when the printed paper cylinder came off the printing machine it dropped directly onto the tines

- chocking the cylinder (photo 5) so that it would not roll off the pallet jack during travel (photo 5), allowing the worker to move and manoeuvre the paper cylinder into position on the dispatch pallet.

The worker chocks the cylinder so it won't come off the pallet jack during travel.

The pallet jack's tines are at the same height of the dispatch pallet, making it a smooth transition. The risk of the paper cylinder overshooting the pallet is minimised by the chock already in place.

The paper cylinder can be deposited onto the dispatch pallet.

Learnings

- The key to building a safety solution is to involve and consult with workers—the experts in performing their work tasks.

- Involvement in the MSBI introduced the business to the principles of Participative Ergonomics for Manual Tasks (PErforM), which provided a useful framework to help workers to identify and control manual tasks risks within their workplace.

- Developing and recording an operating procedure assists with the induction of new staff and ensures consistency of performance.

About MSBI

The initiative was developed in response to an identified over-representation of medium size businesses among workers' compensation claims. The medium size business sector employs about 18 per cent of the Queensland workforce, yet accounts for over 33 per cent of workers' compensation claims lodged each year.