Connecting safety and culture - getting started: Carlton & United Breweries (CUB), Yatala

At CUB Yatala Brewery, safety leadership starts at the top and is visible at all levels of the company. Key components of the company's approach are an authentic value around safety, employee engagement, and integration of safety into business practice. Through this, the company has recorded significant reductions in lost time injuries, reduced insurance premiums, and increased staff engagement.

The safety culture vision

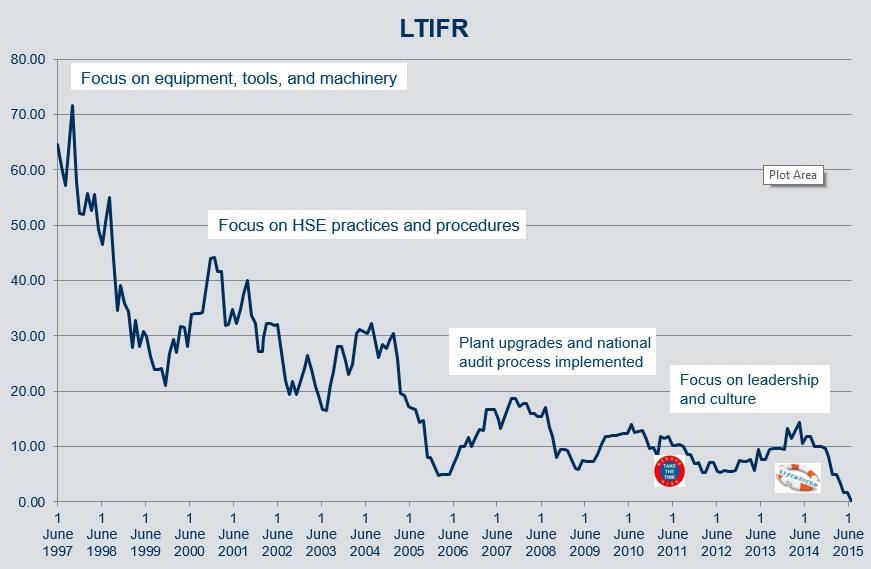

CUB Yatala's safety journey is one of continuous improvement. Over the past 20 years the company has achieved marked improvements in its safety performance through traditional engineering based approaches (e.g. improving the quality of machinery, eliminating hazards), and investment in systems and practices (e.g. introducing standards for health, safety and environment).

However, CUB Yatala management realised that continued improvement in its safety performance required a change in the site culture. Management established a compelling vision that incorporated safety, quality, efficiency, and relationships between people – 'To be the SABMiller Flagship brewery, known for a proud and passionate team that produces quality products safely'.

This vision established a foundation for building the company's safety culture and guided the way CUB Yatala did business, including how safety was prioritised and actioned by leaders at all levels of the company. Put simply, safety was woven into the fabric of how work was done.

Putting safety leadership at work principles into action

CUB Yatala has achieved a positive safety culture outcome by taking multiple leadership and culture actions over time.

| Safety leadership at work principle | Actions |

|---|---|

Good leaders value safety and set a positive example. |

|

Commit to safety, get involved, and inspire others. |

|

Build a safety culture through engagement. |

|

Integrate safety into business practice. |

|

Key initiatives

A number of safety culture initiatives undertaken by CUB Yatala showcase its implementation of the safety leadership at work principles.

CUB Yatala analysed each machine task and developed step-by-step guides. Each step is explained in simple language and supported by pictures of correct operations. These guides are located next to each machine and are readily accessible by operators. Leaders carry out planned audits with operators and step through the instructions, ensuring operator competency and awareness of safety considerations. This process increases employees' safety motivation, improves the leader-worker relationship, and generates informal safety learning.

Following a number of serious safety incidents on one of its manufacturing lines, CUB Yatala halted production and called together employees from across the affected packaging line to identify the cause of the issue. The team looked beyond human error and the individual worker and identified that rushed work due to perceived production pressure was a contributing factor. The 'Take The Time', or 'T3' safety culture initiative was formed, with a site-wide competition to design the campaign logo, which was decided by the workers injured in the initial incidents. The initiative has become part of the site culture and the core message is lived each day by employees.

Visible commitment to safety among leaders is a hallmark of a positive safety culture. Adopting this approach, the senior managers from all departments of the site (including corporate functions such as finance) visit one work area each month. There they have a conversation with a shop floor employee about safety and how it affects their job. Managers use their observations and discussions from these visits to improve how safety and production are managed in their own work areas or across the site as a whole.

CUB Yatala management show their safety commitment by taking part in weekly line tours. During these visits, in a fifteen minute timeframe, managers from different lines inspect a designated line for work health and safety improvements and achievements using a prompt card. Any actions or improvements that are noted are discussed in a group forum after the tour, and healthy competition drives corrective and preventative actions, as managers' own lines are subject to similar scrutiny from fellow managers in a rotational cycle.

As part of safety KPIs for all employees, all site employees must complete a set amount of safety observations each year with particular emphasis on the high risk activities that can cause serious harm (the Lifesavers program). This initiative reinforces CUB Yatala's safety culture and fosters safety leadership at all levels by creating opportunities for employee recognition and feedback, as well as the requirement for the observer to act rather than simply observe and report. (Observations are not accepted if there is no corrected action or follow-up).

At CUB Yatala leading indicators such as safety behaviours, audits, and observations are the main focus of employees' attention, with regular updates and daily discussion during pre-start meetings. Employee engagement in safety is achieved through a transparent leadership style — employees at all levels have immediate and easily-understood access to how the business is performing on safety, quality, and productivity.

Benefits of safety leadership at work

CUB Yatala's efforts highlight the benefits that can be achieved from a safety culture and leadership strategy. In addition to a 49 per cent decrease in insurance premiums over a five year period, the site's lost time injury frequency rate has been in continual decline, with significant improvements since the implementation of their safety culture and leadership strategy.

More information

For further information about this case study, the concepts discussed, or the Safety Leadership at Work Program, visit our website or call 1300 362 128.