Tower crane hoist rope termination assembly failure

Issued: 24/7/2025

Last Updated: 25/7/2025

Purpose

This safety alert highlights the risk of hoist rope termination assembly failures on tower cranes and how to avoid similar incidents.

IMPORTANT - this safety alert supersedes the previous incident guidance document issued by WHSQ on 12 June 2025.

Background

In June 2025, a tower crane (2009 manufacture) was attempting to lift an 11-tonne precast concrete panel when the hoist rope termination (swivel) assembly failed, and the rope detached from the tip of the boom. The panel dropped a short distance onto the semi-trailer that had delivered the panel. However, the hook block dropped approximately 10 metres to the ground along with approximately 80 metres of hoist rope (refer Photograph 1). Although the hook block and hoist rope landed within the exclusion zone and no one was injured, the incident had potential for serious consequences for the rigger in the vicinity, and to others if the precast panel had dropped from height.

Early enquiries indicate the swivel bolt from the rope termination assembly pulled through the castellated retaining nut and disconnected causing the hook block and hoist rope to fall to the ground.

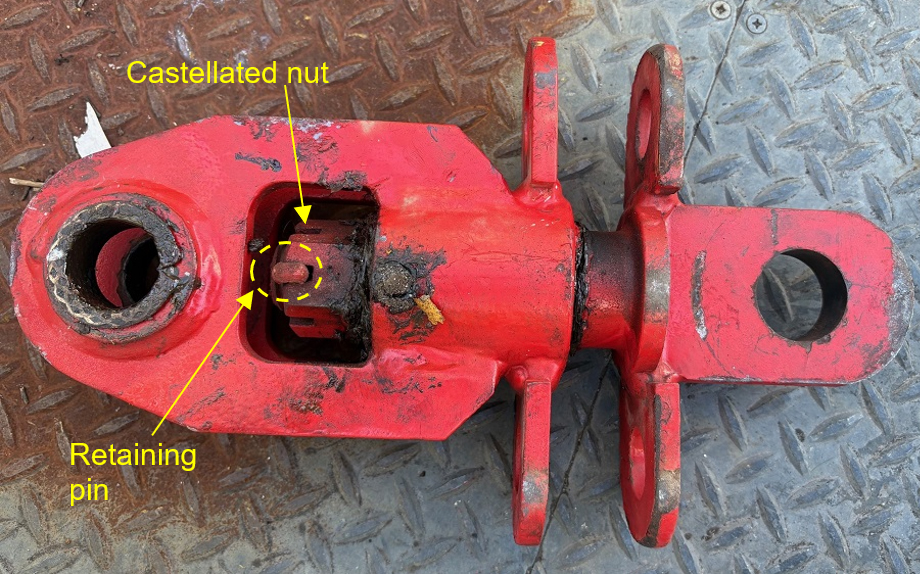

Normally, when the termination assembly is operating as intended, a castellated retaining nut and the threaded section of the swivel connection prevent the termination assembly from separating. A split pin passes through the castellated retaining nut to prevent the nut from loosening (refer Photograph 2 - example of a similar hoist rope swivel termination).

The swivel connection of the termination assembly that failed is shown in Photograph 3. The hoist rope was found to be intact with the castellated retaining nut remaining in position on the upper section of the swivel.

Since 2018, in Queensland there have been at least seven crane incidents where hook blocks and/or loads have fallen for various reasons which is of concern. Further information on two incidents can be found on this WHSQ alert: Mobile and tower crane hoist limits | WorkSafe.qld.gov.au

A similar serious incident occurred in Victoria in 2018 which resulted in the death of one worker and the permanent disability of another. As a result of this incident the crane supplier was convicted and fined $400,000.

Photograph 1: Hook block and wire rope that fell and landed within the exclusion zone.

Photograph 2: A typical example of a hoist rope termination swivel showing castellated nut .

Photograph 3: Failed threaded section on swivel connection that pulled through the nut (split pin passes through hole).

Contributing factors

Initial investigations identified excessive wear and corrosion on the threaded section of both the swivel connection and retaining nut (refer Photographs 4 and 5). The tower crane involved in the recent incident was located close to the ocean and it is understood the tower crane received its annual inspection two months prior to the incident. Despite external corrosion on the swivel assembly, the tower crane involved in the incident was not due to receive its major inspection for several years.

The exact reasons why the incident occurred is currently being investigated.

Photograph 4: Wear and corrosion on threaded connection of swivel bolt.

Photograph 5: Wear and corrosion on thread of the castellated retaining nut.

Action required

The following inspection requirements from the Tower Crane Code of Practice 2017 (the Code) and Australian Standard AS2550.4:2004 Cranes, hoists and winches – Safe use: Part 4 - Tower cranes (AS2550.4) should be followed:

- As part of the annual inspection, section 10.6 of the Code and clause 6.3.5 of AS2550.4 identifies the need to undertake a detailed visual inspection of all structural and wear components, a detailed visual inspection for corrosion and a check of tolerances to ensure they are within the (manufacturer’s) wear limits.

- Section 10.5 of the Code and clause 6.3.4 of AS2550.4, which outline guidance for routine inspections and maintenance, highlight the need for ‘visual inspection and measurements as necessary of structural members and other critical components such as brakes, gears, fasteners, pins, shafts, wire ropes, sheaves, locking devices and electrical contactors’.

- Section 10.3.2 of the Code and clause 6.3.2.2 of AS2550.4 list ‘the condition of ropes and sheaves (e.g. erection, hoisting, counterweight and trolley) and correct rope tracking’ as an item to inspect and test as part of pre-erection inspections.

Although hoist rope terminations and the swivel assembly are not specifically mentioned in these sections, these items are critical components and crucial to the safe operation of tower cranes and should also be thoroughly inspected in accordance with the Code and AS2550.4.

Erected tower cranes

A detailed visual inspection (and measurements if necessary) of erected tower cranes with hoist rope anchorages that incorporate a swivel and nut termination assembly should be carried out as a matter of urgency to ensure they are intact and safe for continued use. Tower cranes erected in a harsh or corrosive environment (such as close to the ocean) should be inspected as a priority. This includes both two and multiple fall anchorages irrespective of whether the hoist rope is terminated at the boom tip or on the hook block.

The detailed inspection should be carried out by riggers experienced at working at height on tower cranes. As with any rigging work associated with tower cranes, riggers should work in pairs with a rescue procedure in place.

The inspection should be carried out in accordance with the manufacturer’s instructions. If the inspection identifies any corrosion (flaking, pitting or loss of material), wear, degradation, deformation, cracks or defects then the swivel assembly is to be replaced with a brand new swivel assembly that complies with the crane manufacturer’s specifications. The replacement swivel assembly could either be brand new or a swivel assembly that has successfully undergone the Enhanced inspection process outlined below.

If there is any doubt about the structural integrity of the split pin or similar locking device, this should be removed and replaced by a brand new unit that complies with the crane manufacturer’s instructions.

Upon completion of the detailed visual inspection of the swivel assembly, a signed report (including photographs) should be completed by the riggers involved and be provided to site management. The inspection report should be readily available on site and be provided to WHSQ Inspectors upon request.

It is to be noted that the WHS Regulation S237 states that a person with management or control of plant that is required to be registered, must keep records of all tests, inspections, maintenance, commissioning, decommissioning, dismantling and alterations. The records must be available for inspection.

Detailed visual inspections of the swivel assembly should continue to be carried out as part of both routine and annual inspections (where the tower crane remains erected for more than 12 months). If the crane has been erected in a harsh or corrosive environment (such as close to the ocean), more frequent inspections may be required – crane owners should consult and seek advice from the crane manufacturer or a suitably competent Professional Engineer (i.e. a Professional Engineer who is a Registered Professional Engineer Queensland).

To minimise corrosion, especially on tower cranes erected in a harsh environment, crane owners should consider additional control measures (e.g. grease, grease tape or other measures specified by the swivel manufacturer or crane manufacturer).

Before the crane is erected at the next construction site, the inspection guidance provided below under Before erecting tower cranes should be followed.

Before erecting tower cranes

Pre-erection inspections allow crane owners to thoroughly inspect the swivel assembly at ground level and replace any components of the swivel assembly, if required. This eliminates the risks associated with working at height and the risk of falling objects.

In view of the latest incident, before the crane is erected, the swivel assembly should undergo the enhanced inspection process as outlined below under Enhanced inspection process. This involves dismantling the swivel assembly to enable a thorough examination of all components and where necessary, replacement of damaged, worn or corroded parts.

The pre-erection inspection report should include documented and photographic evidence that all components of the swivel assembly; including the swivel bolt, bearing, castellated nut and split pin (or similar secondary locking device specified by the crane manufacturer), have been thoroughly inspected and are fit for purpose. This report should be readily available on site and be provided to WHSQ Inspectors upon request.

To minimise corrosion, especially on tower cranes erected in a harsh environment, crane owners should consider additional control measures (e.g. grease, grease tape or other measures specified by the swivel manufacturer or crane manufacturer).

Enhanced inspection process

It is noted that both the Code and AS2550.4 require working components (such as the swivel assembly) be dismantled for examination during a major inspection. Major inspections of tower cranes are mandatory under the WHS Regulation and further guidance is provided in section 10.7 of the Code.

Certain high stress areas and critical components can only be thoroughly inspected when they are dismantled. This latest incident highlights the serious consequences of unidentified degradation or defects in swivel assemblies potentially leading to rope termination failures. It is a reminder of the need for rigorous inspections of hoist rope termination (swivel) assemblies, possibly beyond the current minimum industry benchmarks. If any degradation or defects are identified during routine and/or annual inspection, then the following enhanced inspection process should be carried out for the swivel termination assembly:

- The swivel assembly should be removed and fully dismantled so that a thorough examination of all parts can be carried out, especially the condition of the threads of the nut and threaded connection.

- Detailed visual examination of all critical load bearing areas, in particular the threaded parts of the swivel connection and retaining nut. This includes a check for corrosion and evidence of any deformation or cracking.

- All components of the swivel assembly are to be dimensionally checked against the manufacturer’s allowable wear tolerances.

- Swivel components are to be re-assembled in accordance with the manufacturer’s instructions. Any worn, damaged or corroded components are to be replaced with new components specified by the tower crane manufacturer. Split pins are single use items and will need to be replaced with one that complies with the manufacturer’s specifications (i.e. size, material type, grade and protective coating). The new split pin is to be installed in accordance with the manufacturer’s instructions.

- Photograph(s) should be taken of the replaced components and the brand-new installed split pin.

- A signed and dated inspection certificate completed by the competent person overseeing the inspection should also be provided to site management and kept available to be provided to WHSQ upon request.

Further information

- Work Health and Safety Act 2011

- Work Health and Safety Regulation 2011

- Tower crane Code of Practice 2017 (PDF, 1.56 MB)

- AS2550.4:2004 Cranes, hoists and winches – Safe use Part 4: Tower cranes

- Tower crane hoist rope and brake failures

- Crane owners, operators urged to conduct safety checks