Worker suffers electric shock and causes fire to property

MAY CONTAIN DISTRESSING CONTENT TO SOME READERS

This year, a worker suffered an electric shock when lengths of roof guttering contacted an overhead powerline at a residential construction site.

Initial inquiries indicate an Elevating Work Platform (EWP) was being used to move the lengths of guttering from the roof area to the ground.

The guttering material exceeded the dimensions of the EWP’s platform and guardrails resulting in an overhang. During this task, it appears these materials have come into contact with a nearby overhead powerline, resulting in an electric shock to the worker and a fire at the property.

Investigations are continuing.

These findings are not yet confirmed, and investigations are continuing into the exact cause.

Safety issues

Contact with overhead powerlines or proximity to overhead powerlines can be fatal. You do not need to come in direct contact with them to receive an electric shock. All electric line voltages are lethal, with the risk of flashover increasing as the electric line voltage rises.

The most common electrical risks associated with working near overhead powerlines are:

- electric shock causing injury or death,

- arcing, explosion or fire causing burns (arcing or explosion or both occur when high fault currents are present),

- fire causing property damage.

Hazards from overhead powerlines may arise from:

- something the person is holding, or is in contact with, coming too close to the powerlines (within the exclusion zone),

- operating plant such within the exclusion zone,

- building structures near overhead powerlines.

Ways to manage health and safety

Effective risk management starts with a commitment to health and safety from those who manage the business. If an incident occurs, you will need to show the regulator that you have used an effective risk management process. This responsibility is covered by your primary duty of care in the Work Health and Safety Act 2011.

Use the hierarchy of controls to help decide how to eliminate and reduce risks in your place of work. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. It’s a step-by-step approach to eliminating or reducing risks. You must work through the hierarchy of controls when managing risks, with the aim of eliminating the hazard, which is the most effective control.

Possible control measures to prevent similar incidents

Effective control measures for working near overhead electric lines are often made up of a combination of controls. This includes eliminating the risk of electric shock by turning off the power. The PCBU, principal contractor, or operating plant owner should discuss options for de-energising or re-routing the electricity supply with the relevant electricity entity.

De-energising or re-routing powerlines should be arranged with the electricity entity as quickly as possible as this can take some time. Where overhead powerlines have been de-energised, written confirmation should be sought from the person in control of the powerline before undertaking any work.

If it is not reasonably practical to eliminate the risk of contact with overhead powerlines by de-energising or re-routing powerlines, you must consider using a combination of control measures, to minimise the risk.

If you must work near powerlines, you should follow these steps:

- Develop a safe system of work that ensures a safe distance from powerlines can be maintained at all times (stay outside the exclusion zone).

- Identify overhead powerlines by consulting maps and/or talking to the property owner and electricity entity. For Ergon Energy and Energex, visit Look up and Live map for your free powerline safety plan (this advice must be sought once work is identified to be necessarily occurring within the exclusion zone).

- Consultation regarding the work and the related risks should occur between the PCBU and the plant operator before setting up in the vicinity of overhead powerlines.

- Conduct a site-specific risk assessment and consider:

- Identifying the minimum clearance distance from the closest part of the mobile plant.

- Material that would normally be non-conductive, may become conductive when in contact with high voltage. All materials should be assumed to be conductive unless a competent person can confirm otherwise.

- Unexpected movement of the terrain, ground, or surface upon which the mobile plant is located, possibly resulting in a corresponding surge or sudden movement towards live electric lines.

- Prevailing or unexpected wind strength and direction and other weather conditions.

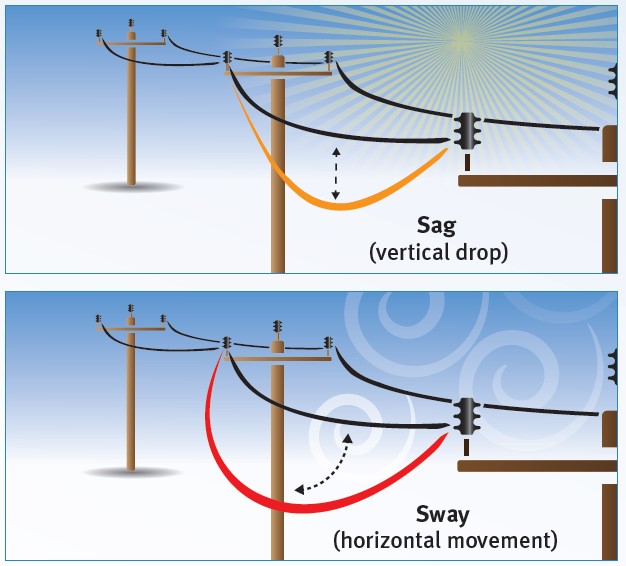

- The possibility of sway and sag of the overhead powerlines (sway of overhead powerlines is usually caused by wind, while sag may vary as temperatures vary).

Avoid entering exclusion zones

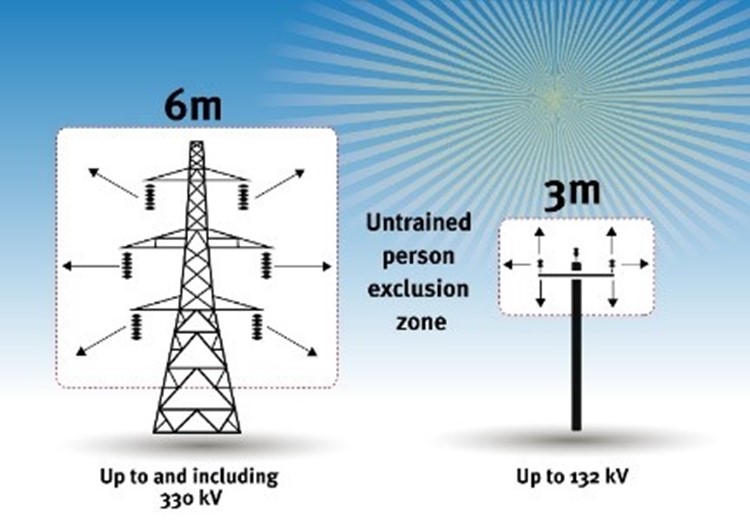

An exclusion zone is a safety envelope around an overhead electric line. No part of a worker, operating plant, or vehicle (this may include items that are being handled or carried) should enter an exclusion zone while the overhead electric line is energised (live). Different exclusion zones apply depending on the level of competence, training, and skills of workers, and whether the worker has been authorised by the owner or person in control of the electric line to work within a closer distance. Examples include:

- Using alternative plant which cannot physically enter the exclusion zone.

- Make powerlines and poles more visible. Contact your electrical entity to discuss installing markers or flags on the powerlines to act as a visual aid to highlight the presence of overhead powerlines.

- Where possible, use insulated or non-conductive tools and equipment.

- GPS geofencing solutions may help keep machinery away from overhead powerline exclusion zones. Electrical detection and alarm systems may also help.

- Using ultrasonic measuring devices instead of the mechanical types for measuring heights of overhead lines.

- Where the mobile plant could enter the exclusion zone, use a safety observer to make sure you stay well clear of exclusion zones. The PCBU is responsible for appointing a safety observer. The safety observer should:

- Not carry out any other work or function that compromises their role as a safety observer such as dogging duties.

- Not be required to observe more than one piece of operating plant at a time.

- Be able to communicate effectively with the operator of the crane or operating plant at all times and should warn the operator about the approach to the exclusion zone.

- Be trained to perform the role.

- Have the authority to stop the operation of the operating plant.

- Follow the safety advice you obtain from your electrical entity.

- Although the following are the minimum safe distances, the best way to stay electrically safe is to maintain the greatest possible distance from powerlines.

Keep your workers and contractors informed about electrical safety: Induct and train your workers and contractors in safe work procedures, emergency procedures, and exclusion zones (Figure 1).

Figure 1: Powerline exclusion zones

- Carefully plan the tasks to be completed near powerlines and work away from them whenever possible, not underneath them. Also avoid storing equipment under powerlines.

- Show your workers the safe distance from a powerline by marking it on the ground.

- Ensure people are aware that powerlines can sag or sway in hot or windy weather (Figure 2).

Figure 2: Powerlines sag or sway in hot or windy weather

- Harvesters, elevating work platforms, cranes, tippers, and excavators, have the potential to enter exclusion zones. Ensure operators know the maximum height and reach of their mobile plant or machinery to be used, and where applicable the nature of the load to be moved.

Elevating Work Platforms

- Elevating Work Platforms (EWPs) include scissor lifts. Some are designed for hard flat surfaces only while others are designed to be operated on rough terrain. Some types are designed for indoor use and are not suitable for windy conditions outdoors.

- If using an EWP at the workplace, you must identify the hazards associated with the use of the EWP and implement control measures to eliminate or minimise those risks so far as is reasonably practicable. The main hazards related to the use of EWPs are:

- contact with electric lines

- overturning the machine

- falling from the work platform, and

- potential crushing hazards when elevating the platform or moving laterally.

- Relevant risk control measures when using EWPs should include:

- Training and instructing workers in the safe operating procedures for the make and model of EWP, as well as safe work procedures to avoid crushing and electrical hazards.

- if carrying out construction work, a PCBU must prepare and Safe Work Method Statement that identifies any high-risk work involved and the controls necessary to implement to ensure the safety of workers i.e. for work at heights and working around energised equipment.

- Training and instructing workers in the safe use of fall arrest equipment and emergency rescue procedures.

- Ensuring an effective operator protective device (secondary guarding) is fitted where there is a risk of crushing against a fixed structure. For more information on secondary guarding, please see this incident alert: Worker killed in elevating work platform incident.

- Ensuring the EWP is only used as a working platform and not as a means of entering and exiting a work area unless the conditions set out in AS 2550.10: Cranes, hoists and winches – Safe use –Part 10: Mobile elevating work platforms are met.

- Ensuring the EWP is only used on a solid level surface, unless it is designed for use on rough terrain.

- Checking the surface area to make sure there are no penetrations or obstructions that could cause uncontrolled movement or overturning of the EWP.

- Checking the bearing capacity of the ground is adequate to safely support the EWP (self-propelled units and truck mounted EWPs with outriggers supported by pads).

- Training and instructing workers in the safe operating procedures for the make and model of EWP, as well as safe work procedures to avoid crushing and electrical hazards.

Caption: Scissor-lift elevating work platform

Source: Managing the risk of falls at workplaces Code of Practice 2021 (PDF, 3.9 MB)

Using an EWP to transport materials should be conducted in accordance with AS 2550.10: Cranes, hoists and winches – Safe use –Part 10: Mobile elevating work platforms, clause 5.13. In addition, you must consider the manufacturer’s specific recommendations in relation to transporting materials.

Freely suspended loads cannot be transported via EWP. If using an attachment (e.g. a material cradle) to transport loads, the following should be planned and any subsequent risks controlled:

- the mass of the attachment and its rated capacity and load limitations,

- the rated capacity of the EWP, including rated capacity of each/any extension decks,

- the effect of wind on the attachment and the load,

- means of securing the load,

- methods for handling the load during loading and unloading,

- size of the load and impact of unevenly distributed loads,

- impact on the operator’s line of vision,

- interference of the load with work platform controls or the operator,

- clearances of the load from electrical conductors,

- clearance of the load from structures,

- effect of the load and attachment on the stability of the EWP,

- effect on access/egress (including in an emergency),

- recovery of work platform,

- for insulated EWPs, the impact of the attachment on the insulation rating of the EWP.

Administrative controls and personal protective equipment (PPE) rely on people behaving as expected and require a high level of supervision. Exclusive reliance on administrative controls and PPE must only occur where other measures are not reasonably practicable or as an interim control while the preferred control measure is being implemented.

The controls that are put in place to ensure electrical safety must be reviewed regularly to make sure they are working effectively.

More Information

- Electrical Safety code of practice 2020 – Working near overhead and underground electric lines (PDF, 0.55 MB)

- Working safely near powerlines in the construction industry (PDF, 1.04 MB)

- Managing the risks of plant in the workplace Code of Practice 2021 (PDF, 1.57 MB)

- Ergon Energy

- Energex

- Powerlink

- Look up and Live map - displays the Energex and Ergon Energy electricity networks

- Exclusion zones

- Worker killed in elevating work platform incident – WHSQ Safety Alert

- AS 2550.10: Cranes, hoists and winches – Safe use –Part 10: Mobile elevating work platforms - subscription required

If this information has caused distress, there are services to help:

- Lifeline – 24/7 crisis support service, including phone, texting and chat services.

- Beyond Blue – information and support for anxiety, depression and suicide prevention for everyone in Australia.

- Black Dog Institute – research and resources on mental health in the workplace.

- SANE – helpline service, as well as resources on mental health.

Have you been affected by a workplace fatality, illness or serious injury?

For advice and support: