Worker seriously injured after being struck by a vehicle

MAY CONTAIN DISTRESSING CONTENT TO SOME READERS

In 2024 a worker suffered serious injuries after being struck by a vehicle at a construction project.

Initial investigations indicate the worker was removing formwork from a stormwater drain when a light vehicle has entered the work area and struck him.

Investigations are continuing.

These findings are not yet confirmed, and investigations are continuing into the exact cause.

Safety issues

Mobile plant and vehicles, can pose potential risks to operators or others nearby, including:

- the vehicle colliding or contacting people or objects such as other vehicles or plant and energised powerlines

- the vehicle moving in an uncontrolled or unexpected manner

- the vehicle overturning

- objects falling on the operator

- the operator being ejected from the vehicle.

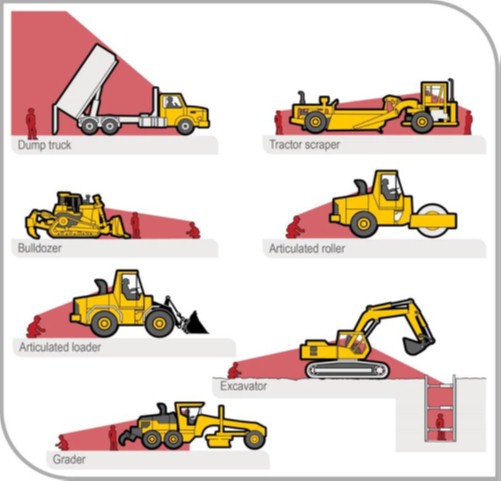

Operators of mobile plant and vehicles can often have severely restricted visibility of ground workers or nearby pedestrians, particularly those close to the plant or vehicle.

Figure 1: examples of blind spots for plant operators.

Source: Excavation work code of practice 2021

Risks and hazards on large construction projects can change rapidly as the work progresses. Workers are at a higher risk of interactions with moving plant and vehicles if effective control measures are not planned and implemented.

Ways to manage health and safety

Effective risk management starts with a commitment to health and safety from those who manage the business. If an incident occurs, you will need to show the regulator that you have used an effective risk management process. This responsibility is covered by your primary duty of care in the Work Health and Safety Act 2011.

Use the hierarchy of controls to help decide how to eliminate and reduce risks in your place of work. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. It’s a step-by-step approach to eliminating or reducing risks. You must work through the hierarchy of controls when managing risks, with the aim of eliminating the hazard, which is the most effective control.

Possible control measures to prevent similar incidents

A project that involves construction work where the cost is more than $250,000 is a construction project. A person conducting a business or undertaking (PCBU) that commissions a construction project is the principal contractor (PC) for the project.

PC’s and PCBU’s have a primary duty to provide a safe workplace environment that minimises the risk of injury to workers within, or adjacent to, the work area.

PCs and PCBUs must first consider controls that most effectively eliminate the risk or, where not reasonably practicable, minimise the risks associated with interaction between plant/vehicles and workers. Elimination involves controlling the hazard at the source. For example, ensuring any path of travel taken by mobile plant or vehicles is away from any area where a person may be required to work.

A PC and PCBU at a workplace must ensure:

- the layout of the workplace allows, and the workplace is maintained to allow, for persons to enter and exit and to move about without risk to health and safety, both under normal working conditions and in an emergency, and

- work areas have space for work to be carried out without risk to health and safety.

A PC, PCBU, contractors and workers are required to control the risk associated with vehicles and mobile plant, including the risk of pedestrians being struck by vehicles. Before operating any vehicle, the person with management or control of it must ensure:

- the vehicle selected is right for the task and is fitted with suitable safety features (e.g. rear-view mirrors and reversing warning device)

- the design and implementation of a traffic management plan, including identifying suitable exclusion zones and communicating these to workers and other persons in the vicinity before tasks are carried out

- the use of a spotter where required, including suitable means of communication between the spotter and operator (e.g. two-way radio) to assist with the safe movement of the vehicle, particularly where there may be blind spots or other workers in the vicinity

- ground conditions and the intended travel pathway have been inspected and assessed to identify any problem areas such as sloping ground

- there is adequate lighting to safely operate the vehicle

- if outdoors, the effect of adverse weather conditions (e.g. reduced visibility) has been considered

- any workers around the vehicle are aware of operator blind spots and exclusion zones.

Traffic management plan

A traffic management plan is a set of rules for managing the movement of traffic in your workplace. It should be developed by the PCBU in consultation with workers and others in the workplace. Everyone affected by the plan must understand it and follow it.

An effective traffic management plan will include broad types of control measures that aim to do the following things:

- keep vehicles and people apart

- limit vehicle movements or speed

- avoid the need for reversing vehicles

- provide a safe area for the driver

- provide clear signage road/area markings

- ensure effective workplace communication.

Workers, visitors and/or others may need to park on the site. Consider setting out a parking area in consideration of the below:

- away from busy work areas and traffic routes

- have walkways leading to and from parking areas which are separated from vehicles or vehicle routes, for example by using physical control measures like barriers or bollards to prevent vehicles from crossing into walking areas

- have barriers, traffic lights or other stop signals where necessary so drivers are aware of when it is safe to leave

- have site access and egress designed to eliminate the interaction of plant, vehicles and people (see Figure 2). Consider the potential risks to people and other vehicles associated with how vehicles or plant enter the parking area from a public road, particularly if entering vehicles and plant are required to slow significantly to safely park.

Figure 2: example of a delineated walkway through carpark to ensure safe access

Source: Adapted from Safe Work Australia guidance material

A PCBU should consider the location of work to be carried out and where applicable, set up an exclusion zone. An effective exclusion zone of a work site will usually include:

- signage informing others of an active exclusion zone,

- visual barriers in the form of any of the below:

- flagging,

- bollards,

- fencing or any other visual barrier.

- communication to workers prior to the implementation of the exclusion and the estimated length of time the exclusion zone is likely to remain.

A PCBU can also consider engineering controls for workers in high-risk zones where plant operates, such as:

- proximity sensors,

- reversing cameras,

- alarms, or

- wearable proximity tags.

PC’s performing construction work must prepare a written work health and safety management plan before starting the project. Every person working on the project must be informed about the plan.

Construction projects are frequently changing and the contractors on site can vary from day to day. To manage a constantly changing work environment, a PC must maintain appropriate consultation, information, and instruction.

Construction works that are carried out at a workplace that involves movement of powered mobile plant (including light vehicles where necessary); is considered high risk construction work, which requires a safe work method statement.

Any remaining risk must be minimised with suitable personal protective equipment. For example:

- hard hats, steel cap boots and high visibility vests

- safety footwear should be:

- suitable for the type of work and environment

- comfortable with an adequate non-slip sole and appropriate tread

- checked regularly to ensure treads are not worn away or clogged with contaminants.

Note: Any administrative control measures and PPE rely on human behaviour and supervision, and used on their own, tend to be least effective in minimising risks.

The control measures you put in place should be reviewed regularly to make sure they work as planned.

More Information

- How to manage work health and safety risks Code of Practice 2021 (PDF, 0.65 MB)

- Managing the risks of plant in the workplace Code of Practice 2021 (PDF, 1.57 MB)

- Managing the work environment and facilities Code of Practice 2021 (PDF, 0.57 MB)

- Mobile plant

- Working in and around mobile plant

- Traffic management guidance plan and example (PDF, 2.01 MB)

- Traffic management guide - Construction work | Safe Work Australia

If this information has caused distress, there are services to help:

- Lifeline – 24/7 crisis support service, including phone, texting and chat services.

- Beyond Blue – information and support for anxiety, depression and suicide prevention for everyone in Australia.

- Black Dog Institute – research and resources on mental health in the workplace.

- SANE – helpline service, as well as resources on mental health.

Have you been affected by a workplace fatality, illness or serious injury?

For advice and support: