Physical demands - grocery store worker - front counter

Note

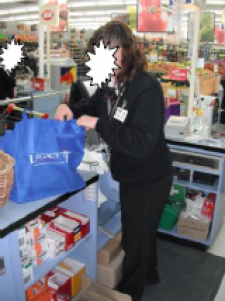

Please note these images are for illustrative purposes only to provide a basic understanding of the tasks involved for this job. They do not necessarily represent compliant or best practice safe work.

Express lane / kiosk

Description of photos

- The express lane workbench was right-to-left feed in these examples, but varied from store to store. It was 900mm high and 800mm deep. There was no conveyor feed for purchased items. The volumes of items handled at the express lanes were less than the regular lanes.

- There were rubber mats on floors.

- There was a plastic bag holder set down below 300mm workbench height, but in most cases the customer's own bag was filled at bench height, meaning the worker did not need to lift the bag.

- Purchased items were obtained from one side of the scanner by one or both hands (photo 1), passed in front of bar code reader at waist height (photo 2, 8, 9) and placed in the customer's bag (photo 3, 12).

- Depending on worker's height a degree of forward leaning and slight truncal twisting was required to work from left to right, or vice versa.

- Various grips were deployed depending on shape and weight of the item, including power grip of various diameters (photo 1), cylindrical grip (photo 2), tripod grip (photo 5), pincer grip (photo 8), lumbrical grip (photo 11) etc.

- Some wrist dexterity as required to angle the items barcode to appose the scanner (photos 8-9).

- The heavier items in the store included 5kg bags of potatoes, 11.25kg soft drink cartons (30 cans), 12kg long-life milk etc. For heavy items “hot keys” were pre-programmed into the computer so that the item did not need to be lifted by customer or worker. In general, stores had a 5kg lifting limit policy. Workers were encouraged to ask for help from supervisor/manager if there were rare occasions that heavy items weren't pre-programmed with hot keys.

- Data may need to be entered via touch screen at chest height with index finger soft touch (photo 10).

- Cash was handled at a 800mm draw, just below workbench height (photo 4).

- EFTPOS machines were linked to computers such that the worker did not need to handle and swipe the bank card; the customer followed prompts and performed the task themselves.

- The cigarettes were stored on shelves at rear of the kiosk area. The highest shelf was at 2100mm, which required a shoulder reach of 135-150° for an average height worker (photo 5). Tripod grip was all that was required to handle packets of cigarettes.

- If the cigarette dispensers needed to be restocked, cartons were obtained from the cupboards below bench that required a squat, kneel or truncal bend to access. The draws of the cigarette cabinet were pulled forward, stock inserted and draw pushed back in.

Regular lanes

Description of photos

- Regular lanes are seen in the photos below. The workbenches were 900mm high, 600mm deep. There were rubber floor mats. Purchased items were fed on conveyor belt from one side of the other. Most stores had a mix of left and right feed (left feed in photo 7 and right feed in photo 11).

- Items were scanned as previously described for express lane.

- Customer's bags were packed at 900mm height as seen in photo 6 and 12, or the bag could be placed on the drop section at 700mm. Either way the worker did not need to lift the full bag; this was the customer's role.

- Sundry other tasks were performed at front end if there were no customers due to be served, including cleaning the surfaces with spray bottle and cloth, tidying magazines, or deployment to the shop floor for facing up etc. this is described elsewhere.

More return to work resources

- Download the return to work checklist (PDF, 0.04 MB) for Grocery retail worker

- View the job task analysis for Grocery store worker – front counter