Fall risk with ring lock type scaffolding

Issued: 6/10/2023

Last Updated: 4/10/2023

Purpose

This safety alert discusses the need for scaffolders to take additional precautions while erecting, dismantling or altering ring lock type scaffolding and for employers to provide additional training and supervision.

Background

Ring lock scaffolding systems are being increasingly used in the building and construction industry. While ring lock scaffolding has specific advantages over other scaffold systems, it can also pose an additional risk of falls, especially for scaffolders who are used to erecting wedge lock type scaffolding. Wedge lock scaffolding is sometimes referred to by the proprietary brand ‘Kwikstage’.

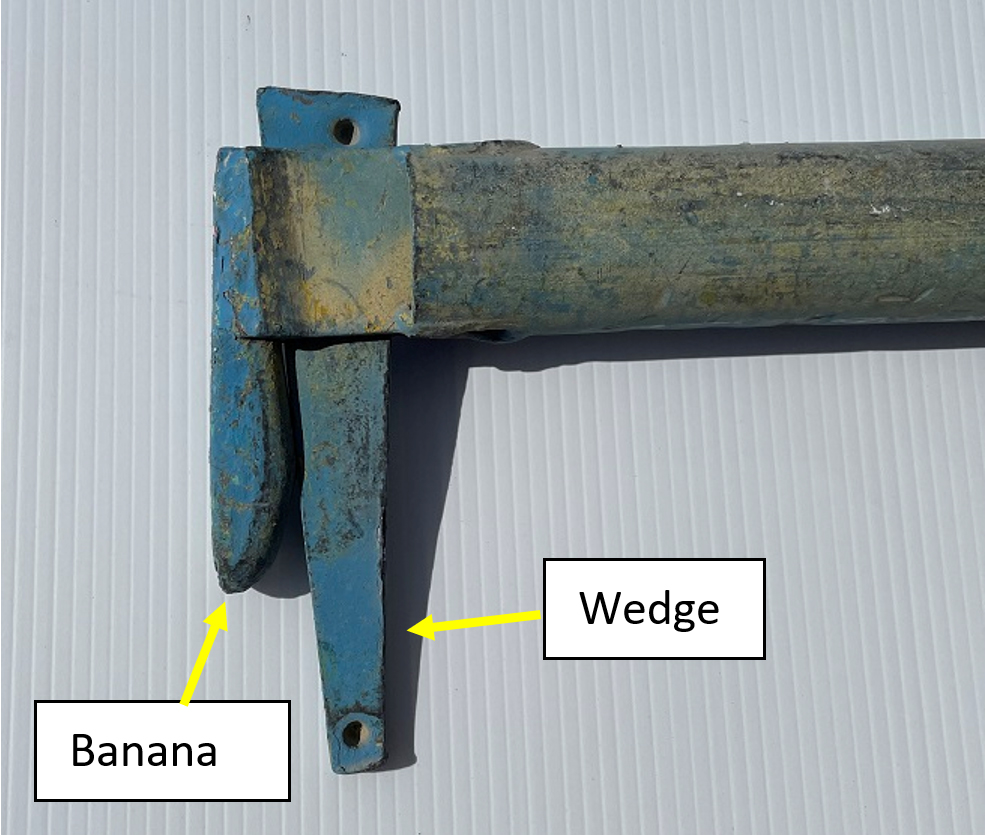

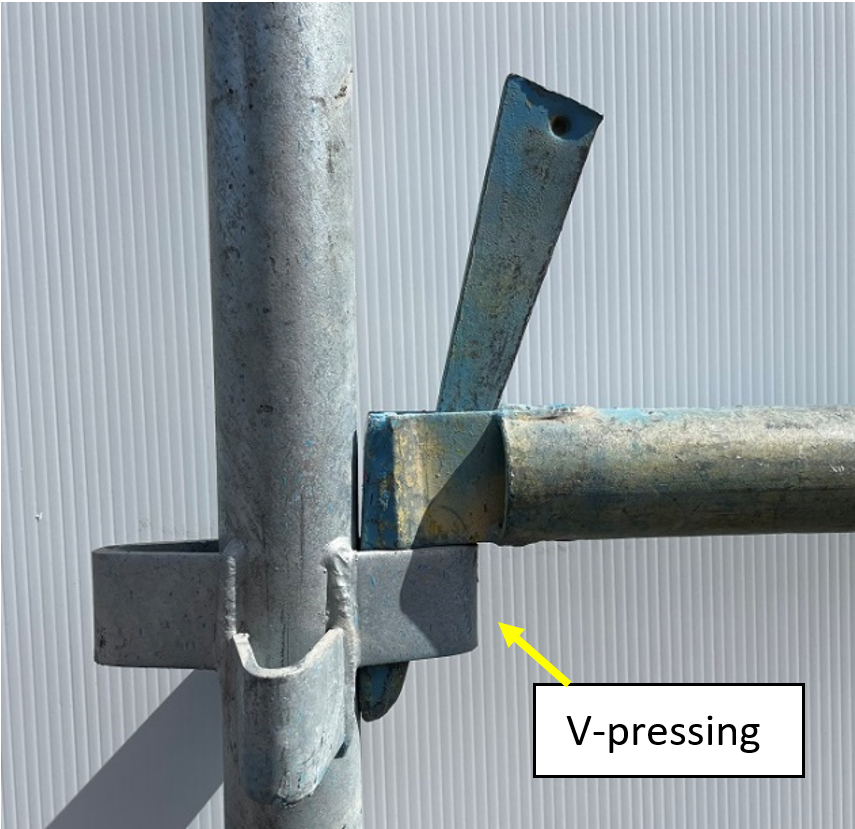

Wedge lock type ledgers and transoms have a moveable wedge and a fixed ‘banana’ at each end (refer Figure 1). When the wedge is disengaged from a ‘v-pressing’, the banana remains captive in the v-pressing until the ledger or transom is lifted upwards (refer Figures 2 and 3). If side loading is applied to the ledger or transom while the bananas are engaged, the member should remain in place.

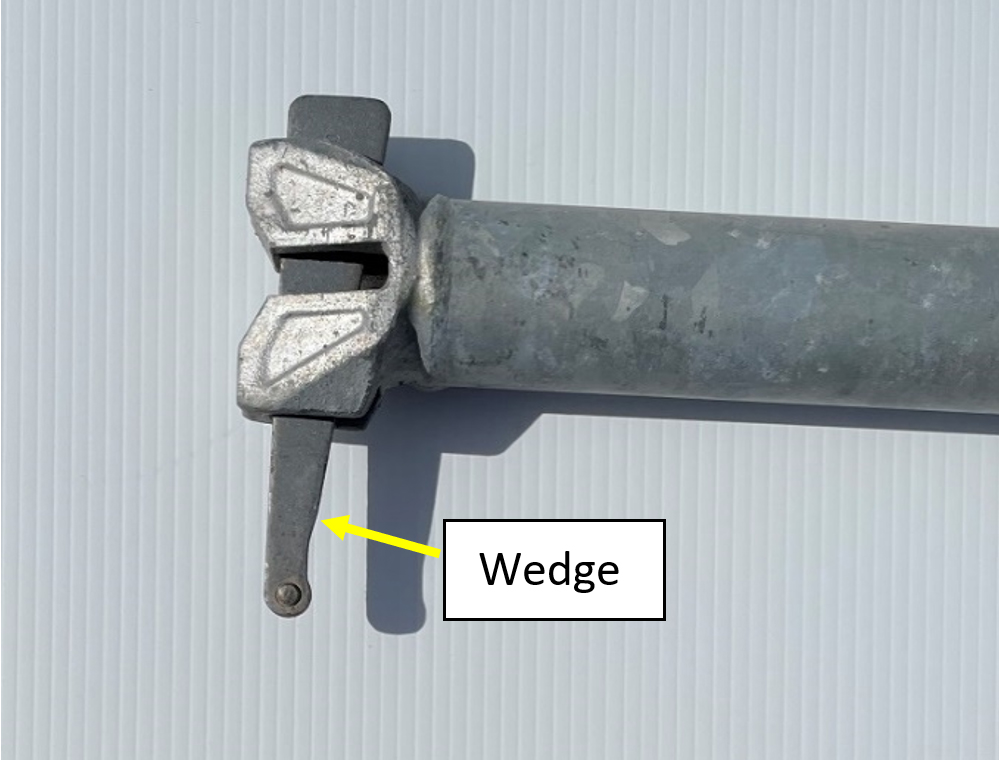

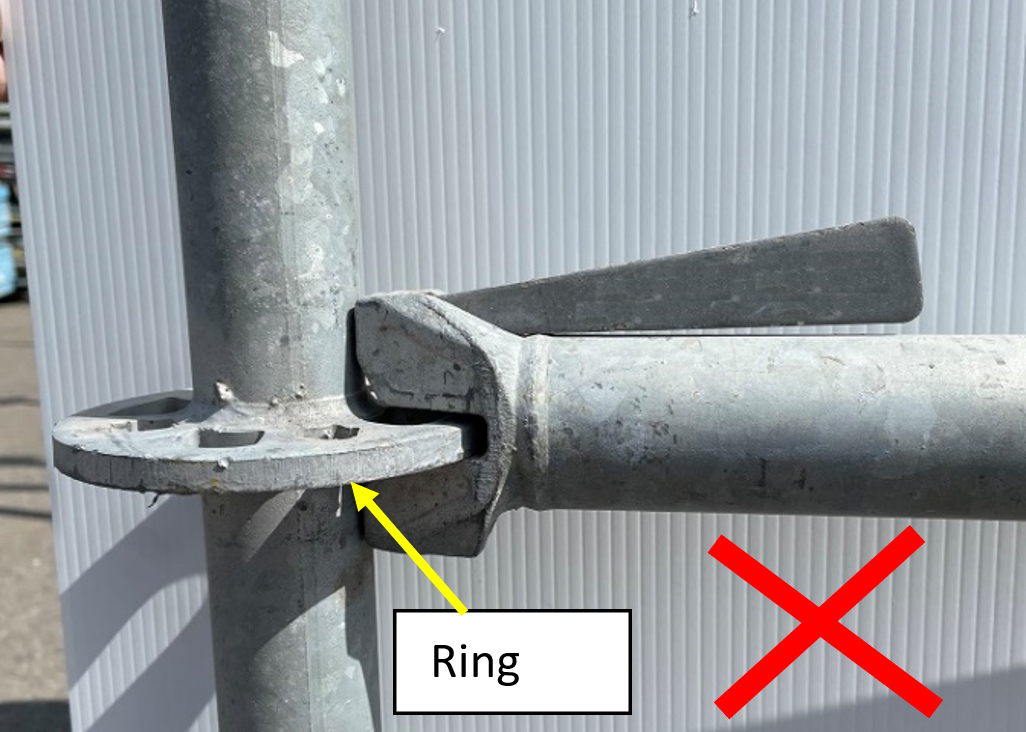

In contrast, on a typical ring lock type scaffold, a ledger or transom only has a moveable wedge at each end of the member (refer Figure 4). When the wedges are disengaged from the ring node, the ledger or transom is free to move sideways and drop off the ring (refer Figure 5). The ledger or transom does not have to be lifted upwards to disconnect from the rings. If a scaffolder inadvertently leans against the member or loses balance with the wedges disengaged, the ledger or transom can slide off the ring causing the scaffolder to fall off the scaffold1.

The risk of serious injury or death when wedges are disengaged (on ring lock type scaffolding), is highlighted by a warning sticker provided by a manufacturer of this scaffold type (refer Figure 7).

Note1: a similar risk can also apply to Cuplock type scaffold when the top cup is lifted – the ledger or transom can rotate and become dislodged. While the bottom spade fitting on Cuplock may provide some resistance to side loading, there is still some risk of dislodgement.

Figure 1 – Wedge lock ledger end view

Figure 2 – Wedge lock ledger installed on v-pressing with wedge disengaged

Figure 3 – Wedge lock ledger with wedge engaged on v-pressing

Figure 4 – Ring lock ledger end view

Figure 5 – Ring lock typical ledger end view installed on ring with wedge disengaged

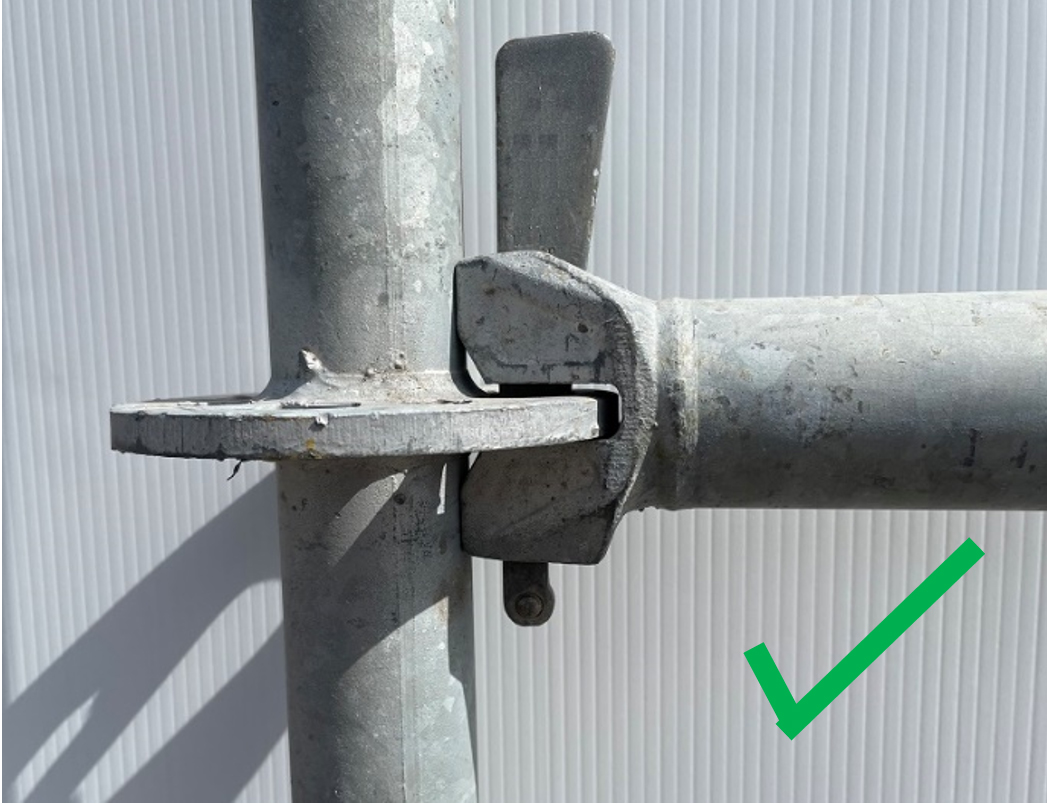

Figure 6 – Ring lock ledger with wedge engaged

Figure 7 – Warning sticker provided by a manufacturer of ring lock scaffolding

Action required

Scaffold employers need to ensure that there is a system of work in-place that minimises the risk of falls. This system of work needs to be strictly followed by scaffolders.

Scaffold systems should be erected in accordance with the manufacturer’s instructions.

Ledgers and transoms on any scaffold system must not be used as a handrail or edge protection unless both ends are secure.

Scaffolders erecting ring lock type scaffolds need to ensure that immediately after placing a ledger or transom on two rings, the wedges are pushed down and locked in place (refer Figure 6). When dismantling, the ledgers or transom should be removed immediately after disengaging the wedges. Ledgers and transoms should never be left sitting on the rings with wedges disengaged.

Scaffold employers should ensure scaffolders have a reasonable level of competency to erect a specific make of scaffold before allowing them to erect, alter or dismantle that type of scaffold unsupervised; this can be done by providing supervision and training to scaffolders. Training should include study of the manufacturer’s documented instructions along with hands-on practical training. Hands-on training can typically be done by a leading hand who has extensive experience in the erection of the specific make of scaffold. Training and supervision should continue until a scaffolder consistently follows the manufacturer’s instructions. In the case of ring lock type scaffolds, this includes a trainee consistently demonstrating the correct sequence of locking and unlocking wedges. Documented records of training provided to scaffolders can help to demonstrate that adequate training has been provided.