Precast wall panel failure

Issued: 06/07/2018

Last Updated: 06/07/2018

Purpose

The purpose of this health and safety alert is to inform workers, employers, builders and designers of the risk of falling concrete elements attached to the perimeter of buildings under construction.

Background

In June 2018, a six tonne pre-cast concrete wall panel fell from the seventh floor of a building under construction. The panel fell to the fifth level floor slab, with scaffolding and formwork sustaining damage (refer Photograph 1). Although no one was injured, the possible consequences for incidents of this type can be severe. The panel had only been lifted into place and attached to the floor approximately four hours before the incident occurred. It appears the panel fixings failed without warning.

Photograph 1: Pre-cast concrete panel after falling. |

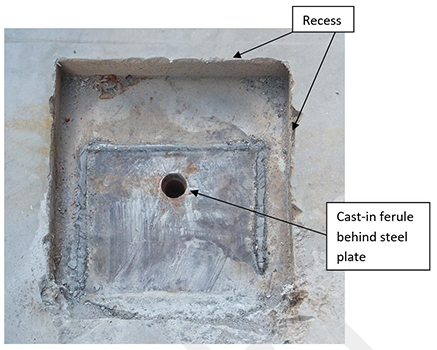

< <Photograph 2: Steel plate cast into panel face showing recess. |

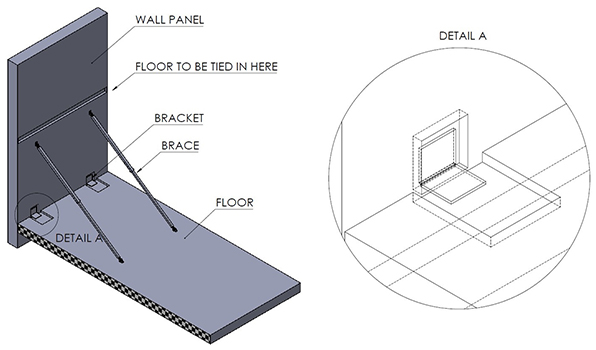

Figure 1: Method used to attach pre-cast wall panel to floor. |

Contributing factors

This incident is currently under investigation and a number of factors may have contributed to the incident. The panel had been attached to a floor of the building by abutting the inside face of the panel to the floor using two “L” brackets (refer Figure 1). The two brackets were welded to steel insert plates on both the pre-cast panel and the concrete floor. The design relied upon the weld integrity and the strength of the bracket for the panel to be supported – the panel was suspended from the brackets. Although two braces were also attached to the panel, these only prevented lateral movement of the top of the panel and failed as the panel fell.

When the concrete floor above was constructed, the top of the panel was to be tied into the floor after removal of the braces. Prior to connecting to the floor above, the design relies on the integrity of the “L” brackets and their connections to keep the wall panel in place. In other words, until the floor above was constructed, days or weeks after the panel was lifted into place, the design relied totally on the integrity of the welds to prevent the panel falling.

It should be noted that the connection plates on pre-cast wall panels were recessed below the level of the concrete surface, so that grout could be applied over the brackets for the panel connections to meet the minimum fire rating specified in the building design (refer Photograph 2).

Action required

It is difficult to justify the use of welding to attach panel brackets to concrete wall panels, where the welded connections are critical safety connections, for the following reasons:

- Inability to prevent panels from moving during the welding process. Even slight movement of the panel can cause the integrity of welds to be compromised. While this issue can be improved by attaching temporary bolted brackets during the welding process, slight panel movement may still be possible.

- Difficulty for the welder to be able to insert the electrode at the correct angle and distance from the weld because the steel plates are recessed below the surface of the concrete panel (refer Photograph 2).

- Difficulty to apply the correct heat for sufficient weld penetration to the cast in steel plates on the concrete panel. Inadequate heat applied to the steel plate will cause the weld to be defective. Excess heat applied to the steel plate may cause an adverse reaction to the concrete under the plate.

- Lack of a comprehensive inspection and testing process to verify the welds comply with the design engineer's specifications. Such a process should include test samples for destructive testing, where the test sample has been welded on site, under the same conditions encountered during the typical welding procedure.

For the reasons highlighted above, the use of welding for critical connections to secure concrete elements on building perimeters should be avoided, particularly where the design relies on these welds for the panel to be prevented from falling off the building.

The use of bolted connections between the panels, brackets and the building is considered a more reliable method than welding. It should be noted that it is already common industry practice for cast-in threaded ferules to be provided on the steel attachment plates (refer Photograph 2).

Any system used for attaching pre-cast elements to building perimeters is to undergo a comprehensive design process by a competent professional engineer, including a signed design verification statement to relevant design standards. In addition, a system for verifying that the design engineer's instructions have been followed should be provided. This will include inspection and sign off of the connections by a competent person.

Further information

Further information on the construction and installation of pre-cast concrete elements:

- Tilt-up and pre-cast construction Code of Practice 2013 (PDF, 0.96 MB)