Stability of stacked material

Published: 23 June 2017

Purpose

The purpose of this safety alert is to highlight the risks associated with stacked materials and to ensure a safe system of work is followed.

Background

In April 2017, a worker was killed when he was struck by falling concrete piles that had been stacked on top of one another at a workplace. The worker was standing next to a stack of three piles and was involved in slinging another pile prior to lifting. The stack of three piles became unstable and crushed the worker.

Contributing factors

There may be several reasons why this type of incident occurs.

Factors contributing to stacked materials falling or toppling may include one or a combination of the following:

- materials are stacked too high and become unstable

- stacked items do not have adequate lateral restraint (i.e. no physical barrier to prevent them falling over)

- the supporting surface is sloping, uneven or soft (rain can quickly change a surface that is otherwise hard)

- unsuitable or damaged packing material is used between stacked elements (e.g. uneven or soft timber)

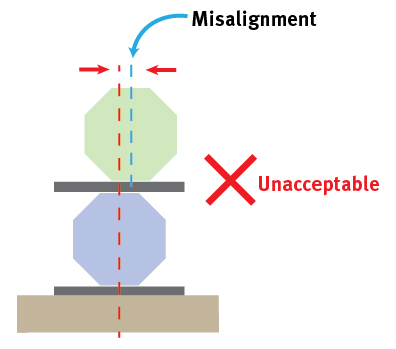

- individual items making up the stack do not align with one another (this can occur because they are not accurately positioned on top of one another when lifted into place). Refer Diagram 1. Note: it is more difficult to achieve precise placement of long piles

- stacked piles do not line up for their complete length due to manufacturing variations

- stacked materials may become unstable if the stack is inadvertently struck by mobile plant operating in the area (i.e. by a forklift or other mobile plant)

- stacked materials may become unstable from vibration (e.g. when a heavy vehicle or machinery is operated nearby).

Diagram 1: End view of stacked long octagonal-shaped piles showing misalignment between top and bottom pile – no lateral restraint provided.

Action required

The storage system should be properly designed by a competent person. Where there is any question about the stability of the stacked material, an assessment should be made by a suitably qualified professional engineer.

If materials of any type are to be stacked, the storage system should ensure:

- Adequate means of lateral restraint is provided to prevent individual items or the whole stack falling over. The lateral restraint method used needs to be able to withstand any inadvertent impact loads arising from handling of the stacked materials.

- The supporting surface is level and has adequate bearing capacity and:

- stored materials and any packing cannot sink, irrespective of the effects of rain

- the area is properly drained and water does not pool in the area

- suitable packing material is used between stacked elements and on the ground to support the stack

- any damaged packing material is discarded and replaced.

- Materials that are bent, damaged or geometrically incompatible for stacking are isolated and not stored in stacks.

- All items in the stack are within the dimensional tolerances specified by the manufacturer. Where this information is not readily available, a competent person such as a suitably qualified professional engineer, should be engaged to assess and determine the maximum bow tolerance of the stack to ensure its stability.

- All vehicles and pedestrians, except those involved in stacking the materials, are excluded from the area.

- The storage system allows for foreseeable collision from vehicles or other mobile plant (e.g. trucks, forklifts or cranes). This is particularly important when workers are working within the stacked area and where mobile plant regularly enters the area. If the stacked area consists of corners that are negotiated by mobile plant, it may be advisable to install bollards.

A method of stacking that is safe for one type of material may not necessarily be safe for another. If there is any doubt about the integrity of the storage system, the safest option may be to lay materials side by side.

Safe work procedures

Safe work procedures for the storage, handling and securing of stacked materials or working near them should be developed and documented by the employer.

The procedures should:

- include an exclusion (no go) zone for workers

- be easily understood by workers on site and preferably include diagrams showing how items should be placed.

Until permanent engineering controls are developed and implemented, safe work procedures should be used to ensure workers are not at risk from stacked materials falling over. Warning signs and barricades may need to be provided.

Any slinging of the elements should be carried from outside the exclusion zone. For example, in the case of concrete piles, the lifting slings may need to be attached and pushed in from the ends with the use of a tool.

Workers should be adequately trained in safe work procedures.

Further information

- Safety alert: Storage and handling of sheet materials

- Tilt-up and Pre-cast Construction Code of Practice 2003 (PDF, 0.96 MB)

- Formwork Code of Practice 2016 (PDF, 1.32 MB)