Access hatches

Published: 5 May 2017

Purpose

The purpose of this safety alert is to highlight the risks associated with removable access hatches.

Access hatches are typically fitted to overhead plant and structures to allow entry into heating, ventilation and air conditioning (HVAC) type ducting, fire extraction systems and suspended ceilings. Where people enter these areas for maintenance purposes, there is a risk of falling through access hatches.

Note: Access hatches used for access between one level and another are sometimes referred to as trapdoors.

Background

Workers have seriously injured themselves when falling through access hatches or trapdoors. More tragically, a worker was killed when he fell 17 metres through an access hatch located on the underside of ducting in an auditorium. The worker had accessed the duct through a different entry point to clean it. Once inside, it appears that the worker unknowingly stepped on the access hatch and fell through the opening. The hatch was never designed to hold a person's weight.

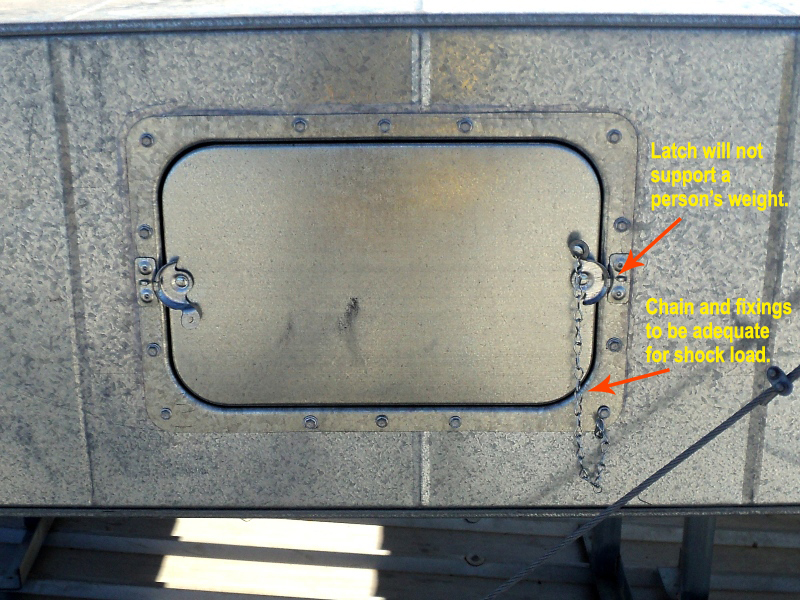

Photograph 1: An example of similar types of access hatches to the one involved in the incident.

Photograph 2: An access hatch fitted to ducting.

Contributing factors

Incidents have occurred when access hatches are:

- not designed to support people inside the duct. Latches used to secure the panel against the frame of the opening may only be designed to compress the 'air-tight' rubber seal

- completely removable and able to fall from the underside of the opening - i.e. the duct frame does not provide any support of the panel to prevent it from falling once the latches are released

- not easily identified by people inside the duct. For example:

- no obvious components (latches or hinges) on the inside of the duct to indicate the panel is a removable access hatch

- no obvious signage or warnings within the duct area to identify the access hatch itself or to warn that it is not suitable for the support of people

- dust and debris on the floor of the duct may obscure workers' view of any difference between the access hatch and the surrounding duct surfaces

- reduced lighting may require time for a worker's eyes to adjust to the lighting level in the duct. Permanent lighting is not normally installed inside ducting.

Action required

Design

Ducting system designers should consider whether a worker can enter the inside of ducting. If so, a professional engineer should design the ducting, supporting members, fixings and any accessible hatches for the loadings for floors that support people as specified in Australian Standard AS/NZS 1170.1:2002 Structural design actions - Permanent, imposed and other actions. AS/NZS 1170.1:2002 is referenced in the National Construction Code (NCC).

Ducting system designers should also consider the following points:

- Alternative designs that would eliminate or minimise the need for workers to access the ducting.

- Environmental vibration and temperature fluctuations (e.g. from operating plant) associated with the duct. This may cause fixings that rely on friction, to self-loosen over time and inadvertently release the access hatch. A falling access hatch has the potential to cause serious injuries when they are located above areas accessed by others.

- Access hatches should not be able to fall when released. Upward opening panels are more likely to be supported by the frame of the opening in the event the latches fail.

- Access hatches should be prevented from falling during normal use by being hinged or secured to the duct structure i.e. with a chain that will withstand any shock loads applied.

- Fixings on access hatches should be robust and remain serviceable for the life of the access hatch.

- Avoid placing access hatches in areas where they can be jumped on, such as directly below another access hatch.

- Design the ducting so that workers accessing them are less likely to place their body weight on the access hatch (e.g. locate the access hatch on the side of ducting).

- Any access hatch accessible from inside ducting should be easily identifiable by being clearly marked with 'Access hatch' and its 'Rated capacity'; or similar. These markings and/or the surface of the access hatch may also be bright contrasting colours to the surrounding surfaces of the duct to improve identification of the access hatch.

- Do not rely solely on administrative controls (e.g. warnings or signage in the vicinity of access hatches not designed to support people) to prevent workers from standing or crawling over them.

Access and use

Businesses should consider using specialist equipment to eliminate or minimise the need for workers to access the inside of the ducting for maintenance, cleaning or repair. Any specialist equipment should only be used by appropriately trained workers.

Prior to commencing work duty holders must identify and manage all risks, including those associated with working at heights and falling objects. The risk assessment must include consideration of the manufacturer's information regarding proper use, maintenance and repair of the ducting and associated equipment.

Some areas of plant and structures accessible via access hatches may also be considered a confined space under the Work Health and Safety Regulation 2011. If so, duty holders must comply with the requirements for confined spaces under Part 4.3 of the regulation.

Before commencing work in an area that may contain access panels at height, ensure:

- all access hatch locations are identified, visually inspected and checked to ensure they are secure and that those accessible from within a duct are designed to support people

- safe work procedures are developed based on the specific site location and type of work to be carried out

- control measures are in place to prevent workers from inadvertently falling through the opened or unlatched access hatch when entering an access hatch

- there is an adequate level of lighting for tasks to be carried out safely

- all workers are trained in the task to be carried out and have the necessary experience and qualifications or licences required for any equipment to be used, such as industrial rope access equipment or elevating work platforms.

Further information

Further information can be sought from the following: