Young worker struck by heavy timber sheets

In September 2022, a 17-year-old work experience student’s pelvis was fractured when a pack of heavy timber sheets fell onto him. The sheets were stacked on their edge and leaning against a wall. Early investigations found the boards weighed approximately 30kg each and the student was retrieving a cover board from the rear of the pack.

These findings are not yet confirmed, and investigations are continuing into the exact cause.

Safety issues

Sheet materials, such as timber, stone and glass, can fall if they are not adequately supported while being transported, handled, or stored. The risk of severe or fatal injuries is high when these materials are stacked on their edges and not adequately supported, restrained or secured from falling by suitable racking or transport frames.

In addition, workers risk musculoskeletal injuries caused by strenuous activity or unexpected movements when heavy items move or change position suddenly while being handled.

Ways to manage health and safety

Taking steps to manage risks is a condition of doing business in Queensland. Effective risk management starts with a commitment to health and safety from those who manage the business. If an incident occurs, you'll need to show the regulator that you’ve used an effective risk management process. This responsibility is covered by your primary duty of care in the Work Health and Safety Act 2011.

Use the hierarchy of controls to help decide how to eliminate and reduce risks in your place of work. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. It’s a step-by-step approach to eliminating or reducing risks. You must work through the hierarchy of controls when managing risks, with the aim of eliminating the hazard, which is the most effective control.

Possible control measures to prevent similar incidents

Effective control measures for moving heavy objects such as heavy sheets are often made up of a combination of controls. The WHS Regulation requires duty holders to work through the hierarchy of control measures when managing certain risks, including risks from hazardous manual tasks.

Some common risk control measures can include but are not limited to the following examples:

- Eliminate stacking sheets vertically by laying sheets on a flat surface horizontally rather than leaning them against a wall or structure

- Using a rack or transport frame to securely store, cradle, lift, transport and restrain sheet materials

- racks and transport frames (including trolleys) should be designed and certified for the loads applied in use

- trolleys should be selected based on the loads to be moved and the ground conditions at the workplace

- include connection points for restraints to ensure the loads remain stable while moving and storing.

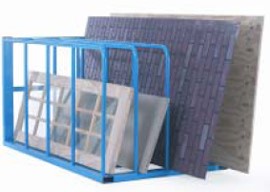

- Racks need to be designed for forces resulting from unbalanced loads. Examples of racking and storage systems for sheet materials are shown in photographs 1, 2 and 3.

Figure 1: An example of storage system for large panels

Figure 2: An example of storing panels of varying sizes

Figure 3: An example of a stacking frame

- Using mechanical aids. Mechanical equipment may eliminate or reduce the need for workers to lift, carry or support items. A wide range of mechanical aids are available, for example:

- cranes (overhead travelling cranes, gantry cranes or jib cranes, stacker cranes, industrial manipulators and articulating arms)

- forklifts

- glass panel, duct and plaster lifters.

- When plant is being used to lift or suspend people or objects, the person with management or control of the equipment at a workplace must ensure, so far as is reasonably practicable, the plant used is specifically designed to lift or suspend the load. The person must ensure the lifting and suspending is carried out:

- with lifting attachments suitable for the load being lifted or suspended

- within the safe working limits of the plant

- using established exclusion zones around the plant and adjoining areas to prevent people from entering the area. The size of the exclusion zone should be based on a written risk assessment.

- Ensure the use of adequate load rated restraint equipment.

- Develop a safe system of work for the movement of sheet materials. This could include, but is not limited to:

- ensuring the workload and pace of work accommodates the physical demands of the manual tasks. Where possible, work should be organised to minimise multiple handling and improve the flow of work. For example, you can improve workflow by:

- having raw materials delivered, located or transferred mechanically to the location or work area where they will be used

- locating storage areas close to distribution areas

- using mobile plant to deliver materials, tools and items.

- ensuring trolleys and other plant and equipment at the workplace are inspected, maintained and repaired according to the manufacturer’s recommendations and specifications. Plant inspection should be conducted in accordance with a regular maintenance system to identify:

- deficiencies in plant or the equipment associated with use of the plant (wear and tear, corrosion and damaged plant parts)

- adverse effects of changes in processes or materials associated with plant

- inadequacies in control measures that have been previously implemented.

- consulting with the manufacturer, workers and others involved in the work to obtain feedback on the plant and associated work processes and safe work procedures.

- providing information, training, instruction and supervision to workers who use the trolleys and other plant and equipment including the development of safe work procedures in accordance with the manufacturer’s instructions that are suitable and adequate to:

- the nature of the work to be carried out by the worker

- the nature of the risks associated with the work (at the time the information, training or instruction is provided)

- the control measures implemented to deal with these risks.

- information available should include the rating for equipment, such as trolleys, that is used at the workplace and what loading limits may apply based on the products.

- ensuring the workload and pace of work accommodates the physical demands of the manual tasks. Where possible, work should be organised to minimise multiple handling and improve the flow of work. For example, you can improve workflow by:

- Any remaining risk must be minimised with suitable personal protective equipment. For example: gloves, hard hats, protective footwear, eye protection, hearing protection.

Adopting and implementing higher order controls, before considering administrative or Personal protective equipment (PPE) controls, will significantly reduce the likelihood of a similar incident occurring. The control measures you put in place should be reviewed regularly to make sure they work as planned.

Young workers

Business owners must also ensure the work environment, and the way young employees do their job, is safe and healthy, regardless of the type and terms of their employment. Employers of young workers should:

- understand young workers' risk profile

- ensure a safe and healthy workplace

- provide information, training, instruction and supervision

- develop a positive workplace culture.

Consider the tasks you give to new and young workers given their skills, abilities and experience. Before a young person begins work, a PCBU should:

- identify the gaps in the worker's knowledge and assess their ability to work safely (competency should be tested)

- it is not sufficient to accept a young worker's assurance that he or she is experienced and competent.

It's important for young workers to actively participate in the way that work health and safety is managed. This means taking induction and training seriously, using the risk management process for work tasks and asking for help before starting a task they're not familiar with or comfortable carrying out.

More information

- Managing risks of plant in the workplace code of practice 2021 (PDF, 1.57 MB)

- Hazardous manual tasks code of practice 2021 (PDF, 1.38 MB)

- How to manage work health and safety risks code of practice 2021 (PDF, 0.65 MB)

- Storage and handling of sheet materials - Alert

- Young workers

- Young worker safety toolkit (PDF, 4.59 MB)

Support for people affected by a serious workplace incident

For advice and support: