Workers struck by moving vehicles

In January 2022, a man died after being hit by a truck a worksite. The worker was part of a crew laying out power lines on the side of the road. Early investigations indicate the man may have been talking on his mobile phone when hit by the reversing truck.

In December 2021, a worker was seriously injured by a reversing road roller during asphalt laying operations at a road work construction site. Initial enquiries indicate the worker was testing the asphalt near the roller which struck him while compacting the road surface.

In November 2021, a worker also lost his life after being hit by an unmanned truck which he may have been warming up.

Investigations are still occurring.

These findings are not yet confirmed and investigations are continuing into the exact cause.

Safety issues

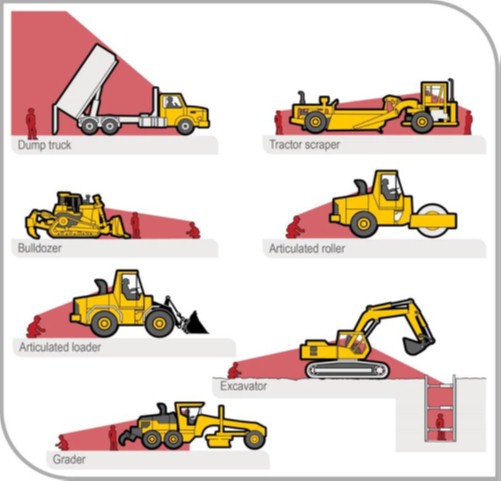

Powered mobile plant includes, but is not limited to, trucks, mobile cranes and earthmoving machinery (e.g. rollers, graders, scrapers, bobcats and excavators). The operation of powered mobile plant exposes workers to a range of risks to health and safety. There have been numerous incidents in Queensland where workers have been seriously injured or killed by powered mobile plant.

Mobile vehicles generally pose potential risks to operators or others nearby, including:

- the vehicle colliding or contacting people or objects such as other vehicles or plant and energised powerlines

- the vehicle moving in an uncontrolled or unexpected manner

- the vehicle overturning

- objects falling on the operator

- the operator being ejected from the vehicle.

Operators of mobile vehicles can often have severely restricted visibility of ground workers or nearby pedestrians, particularly those close to the vehicle.

Figure 1 Source: WHSQ - Excavation work code of practice 2021

Ways to manage health and safety

Taking steps to manage risks is a condition of doing business in Queensland. Effective risk management starts with a commitment to health and safety from those who manage the business. If an incident occurs, you'll need to show the regulator that you’ve used an effective risk management process. This responsibility is covered by your primary duty of care in the Work Health and Safety Act 2011.

Use the hierarchy of controls to help decide how to eliminate and reduce risks in your place of work. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. It’s a step-by-step approach to eliminating or reducing risks. You must work through the hierarchy of controls when managing risks, with the aim of eliminating the hazard, which is the most effective control.

Possible control measures to prevent similar incidents

Employers and self-employed people are required to control the risk associated with vehicles and mobile plant, including the risk of pedestrians being struck by vehicles such as trucks. Before operating any vehicle, the person with management or control of it must ensure:

- the vehicle selected is right for the task and is fitted with suitable safety features (e.g. rear-view mirrors and reversing warning device)

- the design and implementation of a traffic management plan, including identifying suitable exclusion zones and communicating these to workers and other persons in the vicinity before tasks are carries out

- the use of a spotter where required, including suitable means of communication between the spotter and operator (e.g. two-way radio) to assist with the safe movement of the vehicle, particularly where there may be blind spots or other workers in the vicinity

- ground conditions and the intended travel pathway have been inspected and assessed to identify any problem areas e.g. sloping ground

- there is adequate lighting to safely operate the vehicle

- if outdoors, the effect of adverse weather conditions (e.g. reduced visibility) has been considered

- any workers around the vehicle are aware of operator blind spots and exclusion zones

- the vehicle is fitted with and has a working audible warning device. The person with management or control of the mobile vehicle must ensure it has a warning device to alert persons who may be at risk from the movement of the vehicle. There are a number of warning devices that can be fitted to mobile vehicles to alert the operator and others in the workplace including:

- automatic audible alarms which are usually fitted to warn of forward or reversing movement. These alarms emit an intermittent sound which is activated when the gear or drive lever is engaged. The sound should be distinct and clearly audible only in the hazard area.

- motion sensors are used to activate an integrated or separately located alarm. Motion sensors also warn with sound. They are sensitive to movement and are activated by motion in the required direction. These devices are suitable for vehicles that move suddenly in any direction, for example rollers, bulldozers, excavators, boom lifts or scissor lifts.

- lights are usually used to warn of forward and reversing movement. These lights are wired to operate continuously or in hazard mode by flashing, usually when reversing. They generally work when the gear or drive lever is engaged. It is important to choose the intensity and colour of lights appropriate to your workplace to ensure the moving vehicle can be seen.

- radio sensing devices activate when the operator selects reverse. A light and alarm sound inside the cabin to alert the operator if a pedestrian is within a predetermined distance from the rear of the plant.

- trucks are fitted with handbrake alarms to alert drivers the braking system is not engaged before hopping out

- trucks and mobile plant are properly immobilised before being cleaned or worked on (i.e. positioned on level ground and use handbrake and wheel chocks)

- a suitable combination of operator protective devices for the vehicle is provided such as enclosed cabins and seatbelts

- the manufacturer's operating instructions have been read and are followed

- untrained or inexperienced workers should not operate the vehicle, particularly in unfamiliar or high-risk terrain or for unfamiliar tasks

- information, training, instruction or supervision necessary to control the risks associated with the vehicle

- training programs should be practical and ‘hands on’ and take into account the particular needs of workers like literacy levels, work experience and specific skills required for safe use of the vehicle

- ensuring worker training, experience and competency aligns with the requirements and complexity of the task

- training on the make and model of the vehicle should be documented.

PCBUs (Person conducting a business or undertaking) must first consider controls that most effectively eliminate the risk or, where not reasonably practicable, that minimise the risks. Hazards such as pedestrians being struck by vehicles may also be minimised by implementing administrative controls, so far as is reasonably practicable. Administrative controls can include the design and implementation of a traffic management plan.

Traffic management plan

A traffic management plan is a set of rules for managing the movement of traffic in your workplace. It should be developed by the PCBU in consultation with workers and others in the workplace. Everyone affected by the plan must understand it and follow it.

An effective traffic management plan will include broad types of control measures that aim to do the following things:

- keep vehicles and people apart

- limit vehicle movements or speed

- avoid the need for reversing vehicles

- provide a safe area for the driver

- provide clear signage road/area markings

- ensure effective workplace communication.

Adapted from Safe Work Australia guidance material

The best way to protect pedestrians is to make sure people and vehicles cannot interact. This can be achieved by not allowing vehicles into pedestrian spaces or not allowing pedestrians into vehicle operating areas.

However, this may not be always be reasonably practicable and where people and vehicles cannot be separated, the following steps should be considered:

- barriers or guardrails at building entrances and exits to stop pedestrians walking in front of vehicles

- high impact traffic control barriers

- temporary physical barriers, or

- separate, clearly marked footpaths or walkways e.g. using lines painted on the ground or different coloured surfacing.

- pedestrian routes and intersections should be clearly marked, unobstructed, well maintained and well lit

- supervision of the exclusion area and good communication between the supervisor and plant operator will ensure access to exclusion zones is limited to authorised personnel

- cameras may be fitted to allow operators vision in the vehicles ‘blind spots’ (areas usually obstructed or unable to be seen from the operator’s perspective, see Figure 1)

- use of spotters.

If the risk from using mobile communication devices when operating (or from just being around) mobile or high-risk plant is significant, then using these devices should be prohibited if it is reasonably practicable.

To do this effectively you need to prevent all access to the devices when the risk is present, for example by ensuring they are surrendered and stored away.

When this is not reasonably practicable, risks can be minimised by implementing a mobile device usage policy and ensuring everyone complies with it.

Such a policy can include:

- using hands-free devices

- using two-way radios instead of mobile phones

- keeping conversations short

- limiting use to times when plant is inactive

- limiting use to designated areas (eg exclusion zones)

- limiting non-essential use (eg emergencies only)

- prohibiting the use of mobile phones in hazardous situations (eg when performing complex tasks with machinery, refuelling plant)

- keeping a sufficient distance from others who may be put at risk if distracted by your communication

- discussing risks of inappropriate use with workers.

Adapted from Safe Work NSWMobile communication devices | SafeWork NSW

Any remaining risk must be minimised with suitable personal protective equipment. For example:

- hard hats, steel cap boots and high visibility vests

- safety footwear should be:

- suitable for the type of work and environment

- comfortable with an adequate non-slip sole and appropriate tread

- checked regularly to ensure treads are not worn away or clogged with contaminants.

Administrative control measures and PPE rely on human behaviour and supervision. If used on their own, they are least effective in minimising risks. The control measures you put in place should be reviewed regularly to make sure they work as planned.

More information

- How to manage work health and safety risks code of practice 2021 (PDF, 0.65 MB)

- Managing risks of plant in the workplace code of practice 2021 (PDF, 1.57 MB)

- Managing the work environment and facilities code of practice 2021 (PDF, 0.57 MB)

- Mobile plant

- Work health and safety consultation, co-operation and co-ordination code of practice 2021 (PDF, 0.49 MB)

- Traffic Management for Construction and Maintenance Work code of practice 2008 (PDF, 0.8 MB)

- Onsite traffic management self-assessment tool (PDF, 0.36 MB)

- Onsite traffic management (Powerpoint presentation) (PPTX, 1.24 MB)

- New guide to on-site traffic management

- Workers struck by mobile plant

- Safely immobilising heavy vehicles and trailers campaign

Support for people affected by a serious workplace incident

For advice and support: