Worker seriously injured by slicing machine

In December 2022, a worker suffered serious lacerations and broken bones to all four fingers on one hand from a slicing machine blade.

Early investigations revealed the machine was used to slice dry meat products. It appears the worker was cleaning waste material from an area next to the blade with a guard raised.

Investigations are continuing.

These findings are not yet confirmed, and investigations are continuing into the exact cause.

Safety issues

Machinery, including meat slicers, often has several different types of moving parts. There are significant risks associated with machinery and using it unsafely can cause severe injuries including:

- limbs amputated by unguarded moving parts

- fractures sustained while accessing, operating or maintaining machinery

- electric shock from machinery that is not adequately protected or isolated.

Hazards associated with meat slicing or similar machines include but are not limited to:

- access to the cutting blade while it is moving

- operating the machine while covers or guarding are removed or opened

- no emergency stop device within the operator's reach.

Ways to manage health and safety

Taking steps to manage risks is a condition of doing business in Queensland. Effective risk management starts with a commitment to health and safety from those who manage the business. If an incident occurs, you'll need to show the regulator that you’ve used an effective risk management process. This responsibility is covered by your primary duty of care in the Work Health and Safety Act 2011.

Use the hierarchy of controls to help decide how to eliminate and reduce risks in your place of work. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. It’s a step-by-step approach to eliminating or reducing risks. You must work through the hierarchy of controls when managing risks, with the aim of eliminating the hazard, which is the most effective control.

Possible control measures to prevent similar incidents

A person conducting a business or undertaking (PCBU) has duties under WHS legislation to ensure, so far as is reasonably practicable, the provision and maintenance of safe plant. The WHS Regulation includes more specific requirements for PCBUs to manage the risks of plant, as well as other hazards associated with the workplace.

Eliminating potential hazards at the design or planning stage enables the incorporation of risk control measures that are compatible with the plant’s original design and function requirements. Designers, manufacturers, importers and suppliers of plant, must ensure, so far as is reasonably practicable, the plant, they design, manufacture, import or supply is without risks to health and safety.

Effective control measures for plant and machinery include a combination of controls. Some risk control measures can include but are not limited to the following examples:

- Guarding - physical or other barriers that increase safety for operators and others involved in the normal operation, servicing and maintenance of machines. Types of guarding:

- a permanently fixed guard if access to parts of the plant is not necessary during operation, maintenance, or cleaning

- an interlock guard is connected to the plant's operating controls so the plant can't operate when the guard is open. The guard should not be able to open or be removed until the moving parts (i.e. cutting blade) have stopped. Similarly, when an interlocked guard is re-closed, the machine should not automatically restart.

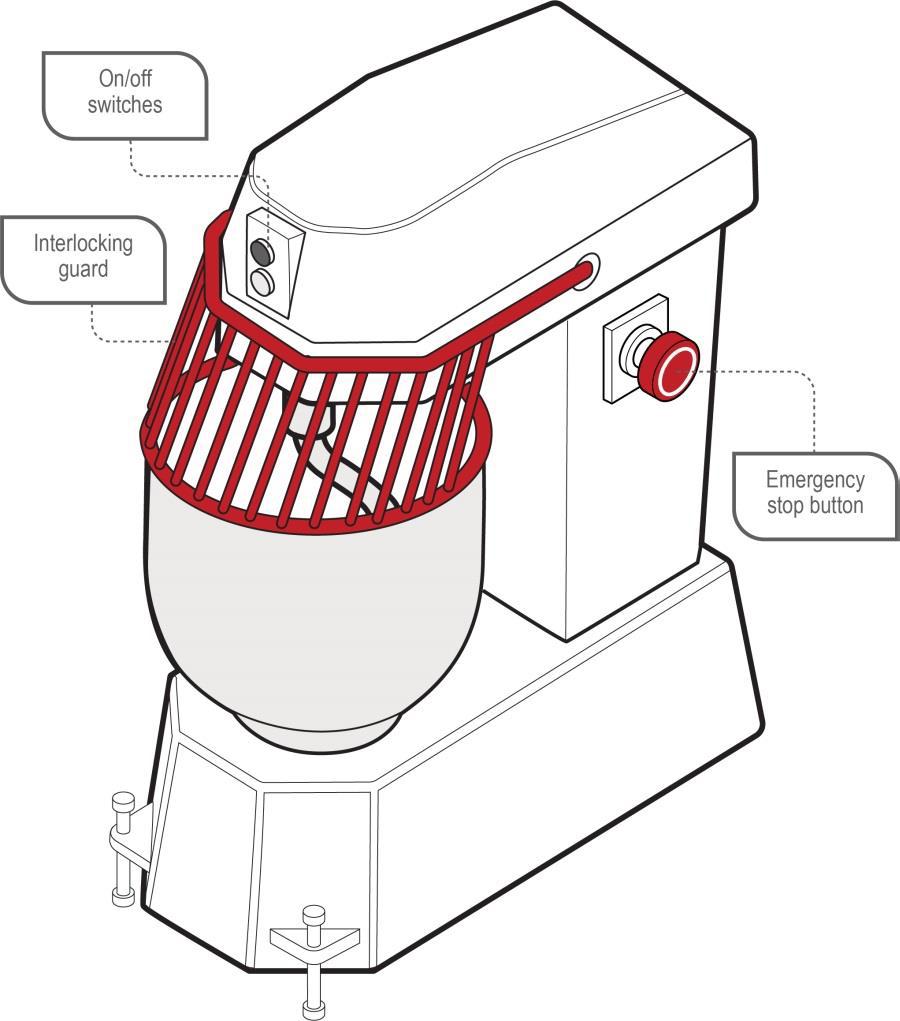

In Figure 1 below, the hinged top guard on the food mixer has a positively operating insertion key which automatically cuts off the plant's power when the lid is opened or removed. This allows the blades to come to rest. If the moving parts do not stop immediately once the power is cut off, then a guard should be designed to delay release of the locking mechanism until the moving parts have stopped.

Figure 1: Food mixer with interlocking guard

Source: Managing the risks of plant in the workplace Code of Practice 2021 - a fixed guard, which can only be altered or removed with a special tool not normally available to the machine operator

- a presence sensing system which detects when a person (or part of a person's body) enters the danger zone and stops a machine. Photoelectric light beams and laser scanners are examples of these type of guards. They rely on sensitive trip mechanisms and their placement should be determined by a specialist.

- Providing suitable tools to prevent the need for workers to enter the danger zone for clearing blockages.

Risks can be further minimised by implementing administrative controls such as a safe system of work and personal protective equipment (PPE) controls. This could include, but is not limited to:

- implementing an isolation procedure which involves a lock out/tag-out process and procedure to ensure the plant is isolated and de-energised from all energy sources prior to workers accessing any parts of the machine. This ensures the plant cannot be inadvertently operated while workers are clearing blockages, performing maintenance or cleaning work. The process may include:

- shutting down the machinery and equipment

- identifying all energy sources and other hazards

- identifying all isolation points

- isolating all energy sources

- controlling or de-energising all stored energy

- locking out all isolation points

- tagging machinery controls, energy sources and other hazards

- testing by ‘trying’ to reactivate the plant without exposing the tester or others to risk

- providing information, training or instruction to workers that is suitable and adequate in a way that is readily understandable. This includes safe work procedures with instructions on:

- the correct use of guarding and other control measures

- how to safely access, operate and maintain the plant

- cleaning processes according to the manufacturer’s instructions

- retaining all operating manuals and instructional material provided by the manufacturer to correctly operate and maintain the plant

- consulting with workers as early as possible when planning to introduce new plant or change the way plant is used. Workers should be encouraged to report hazards and health and safety problems immediately so the risks can be managed

- the inspection of plant is conducted in accordance with a regular maintenance system to identify:

- deficiencies in plant, for example; wear and tear, corrosion and damaged parts

- adverse effects of changes in processes or materials associated with the plant

- inadequacies in control measures that have been previously implemented

- protective footwear, eye protection, hearing protection, and high visibility clothing.

Administrative control measures rely on human behaviour and supervision, and used on their own, tend to be least effective in minimising risks. The control measures you put in place should be regularly reviewed to make sure they are effective.

More information

- Managing risks of plant in the workplace code of practice 2021 (PDF, 1.57 MB)

- Machine guarding - film

- Isolating machinery when not in production - film

- Guide to machinery and equipment safety (PDF, 1.46 MB)

Have you been affected by a workplace fatality, illness or serious injury?

For advice and support: