Fall from construction site scaffold

In October 2021, a worker fell approximately 3.5m from a scaffold bay extension platform (hop up) onto a scissor lift at a construction site, sustaining serious injuries.

Early enquiries indicate the worker was painting exterior cladding at the time of the incident. For reasons yet to be established, the hop up brackets have separated, releasing the metal scaffold planks causing the worker to fall.

Investigations are continuing.

These findings are not yet confirmed, and investigations are continuing into the exact cause.

Safety issues

The erection, alteration, use and dismantling of a scaffold exposes workers to the risk of a serious fall or being struck by falling objects, such as scaffold components and tools. There is even a risk of scaffold collapse. In addition, unauthorised access, use or alteration of a scaffold can affect its integrity and introduce significant hazards and risks (e.g. the risk of a worker falling from height, if a part of the structure is removed).

A scaffold can be in place for a significant length of time, with many different workers from various trades having access to and using the scaffold. This means the scaffold could potentially be altered or tampered without the person with management and control of it being aware. A scaffold may be altered, for example, to provide ease of access for specific work activities, and the consequences of these alterations may not be understood.

Ways to manage health and safety

Taking steps to manage risks is a condition of doing business in Queensland. Effective risk management starts with a commitment to health and safety from those who manage the business. If an incident occurs, you'll need to show the regulator you’ve used an effective risk management process. This responsibility is covered by your primary duty of care in the Work Health and Safety Act 2011.

Use the hierarchy of controls to help decide how to eliminate and reduce risks in your place of work. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. It’s a step-by-step approach to eliminating or reducing risks. You must work through the hierarchy of controls when managing risks, with the aim of eliminating the hazard, which is the most effective control.

Possible control measures to prevent similar incidents

The principal contractor for a construction project, or the PCBU with management or control of a construction site, has ultimate responsibility for ensuring systems are in place to maintain a safe work environment on the scaffold and each PCBU using the scaffold leaves the scaffold without risks to health and safety. In managing unauthorised access, use or alteration of a scaffold, the Work Health and Safety Regulation 2011 requires specific control measures to be implemented, where it is reasonably practicable to do so.

You must consider various control options and choose the control that most effectively eliminates or minimises the risk in the circumstances. These can include but are not limited to the following:

- Scaffold plans - A scaffold plan needs to be prepared for scaffolding work above 4m measured from the top working platform to the ground and provided by the PCBU doing the scaffolding work. All scaffolds should be built in accordance with the relevant Australian Standard (AS/NZS 1576 Scaffolding). What is constructed on site should reflect what is in the scaffold plan.

- Working Platforms - ensuring each scaffold is designed to carry the required number of working platforms and to support live loads. Scaffold planks should:

- comply with AS 1577 Scaffold planks and have a slip-resistant surface

- not be cracked or split

- be of uniform thickness

- be captive (i.e. cannot be kicked off) and fixed to prevent uplift or displacement during normal use.

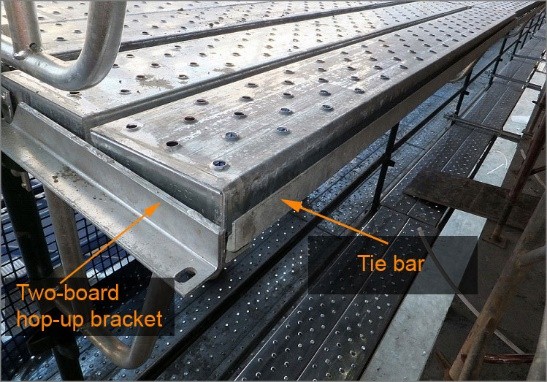

- Hop up brackets - all hop-up brackets (apart from single board hop-up brackets) should be provided with tie bars to stop brackets from spreading apart and causing planks to dislodge, unless otherwise specified by the scaffold manufacturer. No single inadvertent force should be able to dislodge a tie bar pin (without a scaffolding plank sitting on top of the bar), or any part of a tie bar (e.g. a bouncing motion caused by an object falling down on the scaffolding deck).

An example of a tie bar on a two-board hop-up bracket is shown in below. In this image, the scaffold plank is sitting on part of the tie bar which helps to keep the tie bar in place.

- Administrative controls – can be used to support other control measures and may include a safe system of work that prevents alterations to or interference with the scaffold that is not authorised by the designated person. These may include:

- consulting the scaffold designer before making any alterations

- ensuring only a competent person makes scaffold alterations (e.g. a worker with the appropriate High Risk Work License as a Scaffolder).

- scaffold alterations are undertaken in accordance with the scaffold plan

- alterations do not compromise the structural integrity of the scaffold

- having systems in place (e.g. regular inspections) to identify unauthorised interference with the scaffold. Safe work procedures should be developed for the inspection and maintenance of scaffolds and scaffolding components to ensure they remain safe. The inspection of a scaffold on site is particularly important when it is in place for a long time.

- providing workers with information, training and instruction on the nature of the scaffolding work, the risks associated with scaffolding and the control measures implemented to reduce that risk. This may include information, training and instruction on:

- emergency response procedures

- what loads the scaffold can safely take (Safe Working Load (SWL))

- not to make unauthorised alterations to the scaffold, such as removing guardrails, planks, ties, hop-up bracket tie bars, toe-boards and braces

- keeping working platforms clear of debris and obstructions along their length

- never accessing incomplete or defective scaffolds

- immediately reporting defects if they occur

- the requirement for a written safe work method statement (SWMS) to be developed for any work carried out at or above 2m.

More information

- Scaffolding code of practice 2021 (PDF, 1.63 MB)

- Managing the risk of falls at workplaces code of practice 2021 (PDF, 3.9 MB)

- How to manage work health and safety risks code of practice 2021 (PDF, 0.65 MB)

- Scaffolding hop-up bracket tie bars

- Scaffolding

Support for people affected by a serious workplace incident

For advice and support: