Safety of moving walks and escalators

Issued: 3/3/2022

Last Updated: 3/3/2022

The purpose of this safety alert is to highlight the risks of missing pallets/steps on moving walks and escalators.

Persons conducting a business or undertaking (PCBUs) with management or control of moving walks and escalators should ensure that control measures, such as missing step sensors, are fitted and located at the appropriate position to eliminate or minimise, so far as is reasonably practicable, the risk of falling into a moving walk or escalator.

In some cases, older plant may require an assessment and review of the control measures fitted to ensure that adequate control measures are fitted and remain effective to control the risk.

Background

Workplace Health and Safety Queensland (WHSQ) is aware of two incidents where moving walks were found operating with a missing pallet. In both cases, action was taken by staff to stop the moving walks.

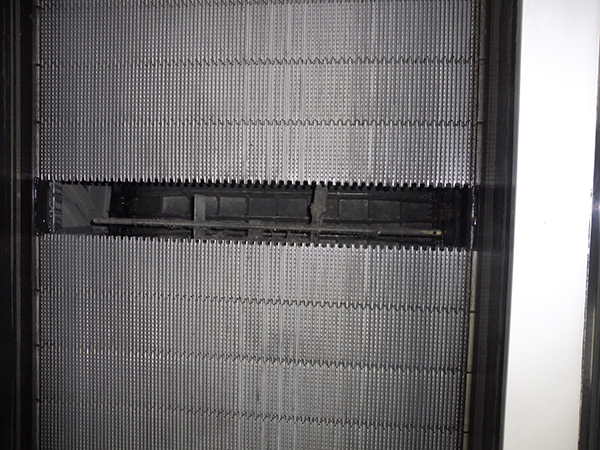

A missing pallet leaves a gap in the standing space, which puts people at risk of falling into the moving walk. If someone fell through the gap created by a missing pallet, they would likely be seriously injured by the moving machine parts of the moving walk.

This risk may apply to escalators as well as moving walks.

Photograph 1: A moving walk with an exposed gap due to missing pallet. Source: SafeWork SA

Photograph 2: The view through to the internal areas of the moving walk. Source: SafeWork SA

Contributing factors

Moving walks and escalators contain numerous moving parts that require routine maintenance and inspection. It is important that maintenance and inspection are undertaken in accordance with the manufacturer’s recommendations and defined timeframes.

When worn, damaged, or out of tolerance components are not promptly identified and rectified, they can cause failures. Failures of the retaining system, used to secure pallets/steps, can result in pallets/steps falling or becoming dislodged.

Fallen or dislodged pallets/steps should be detected by safety devices (switches and/or sensors) and the moving walk or escalator safely stopped before anyone is exposed to the associated risk. Examples of these safety devices include:

- A step sag device designed to detect when a step or pallet is sagging and stop the escalator or moving walk prior to it reaching the end of the moving walk or escalator (i.e. prior to the comb intersection line).

- A missing step device designed to detect when a step or pallet is missing before the gap emerges from the start of the moving walk or escalator (i.e. prior to emerging from the comb).

Ensure the correct safety device is used for the correct application. A step sag device (or similar device that detects sagged or dislodged pallets) is not appropriate for detecting a missing step.

Switches and sensors all have limitations in their application and use as a safety device. When a switch is used as a safety device, the functioning of that switch should ensure that it is capable of detecting the desired fault in all circumstances. Similarly, both switches and sensors need to be correctly positioned to detect hazardous situations and stop the escalator or moving walk before an incident occurs. The design of the safety related parts of the control system should include features to detect any failure of safety devices.

In both incidents, the gap created by the missing pallet emerged from the start of the moving walk and exposed people to the risk of injury or death. In the first incident involving an older moving walk (installed in 2006), an adequate missing step device was not present, resulting in the moving walk continuing to operate while a pallet was missing. In the second incident involving a newer moving walk (installed in 2016), missing step devices were present on the underside of the moving walk, however the pallet is believed to have fallen and left a gap after the missing step sensing location, allowing the gap to emerge from the comb.

It is possible that moving walks and escalators may not be fitted with missing step devices or fitted with ineffective or incorrectly positioned missing step devices that are unable to detect a missing pallet/step before the gap emerges from the comb. Since 2015, AS 1735.5.1 Lifts, Escalators and moving walks Part 5.1: Safety of escalators and moving walks – Construction and installation, includes specific requirements for the detection of missing pallets or steps.

Action required

The Work Health and Safety Act 2011 (WHS Act) sets out duties for a person conducting a business or undertaking (PCBU) that design, manufacture, import, supply and install plant as well as the primary duty on a PCBU. These duties, in part, require that a PCBU ensures, so far as is reasonably practicable, that the plant is without risks to the health and safety of any person.

The WHS Act also imposes duties on a person with management or control of plant at a workplace. A person with management or control of moving walks or escalators must ensure, so far as reasonably practicable, they are without risk to the health and safety of anyone who uses it. This duty takes precedence over any requirements in technical standards.

Where a new hazard or risk is identified, or a control measure is found to no longer be effective, a PCBU must review and, as necessary, revise the control measures to ensure plant, including moving walks or escalators, are without risks to health and safety. Revised controls measures must be selected using the hierarchy of control measures.

Incidents and notifications

The WHS Act also defines “dangerous incidents” which includes the failure, malfunction or damage to any plant that is required to be registered. A dangerous incident is required to be notified. The failure of the moving walks described above would be a dangerous incident which requires notification. Anyone can notify WHSQ of an incident but there are duties on PCBUs to ensure notifiable incidents are notified.

PCBUs with management or control

PCBUs with management or control of moving walks and escalators should:

- Ensure that all maintenance, inspection, testing, and service bulletin activities that relate to the safe operation of moving walks and elevators are completed by a competent person in accordance with recommendations of the manufacturer or a competent person. It may be necessary to confirm that all current service bulletins are available to the service providers. Some manufacturers require the replacement of clips and fasteners that attach the pallets to the chain every time they are removed. Other requirements for tightening torque and thread locking may also be specified by manufacturers.

- Keep records of all tests, inspections, and maintenance under Section 237 of the Work Health and Safety Regulation 2011. These records must be available for inspection. PCBUs should ensure they get copies of these records from their maintenance provider.

- Have a competent person review the current safety features fitted to the moving walks or escalator under your control. If no missing pallet/step safety devices are identified you will need to implement controls measures to eliminate, or minimise so far as reasonably practicable, the risk to persons from a missing pallet or step.

- If missing pallet/step safety devices are fitted, the competent person will need to assess whether the function and positioning of the safety devices ensures the moving walk or escalator will be stopped before any gap emerges from the comb.

If you are unsure whether this is applicable to the moving walks and escalators under your control, it is recommended you discuss this alert with your maintenance provider.

Designers, manufacturers, importers and suppliers

Designers, manufacturers, importers and suppliers of moving walks should:

- Ensure control measures are incorporated into the design of moving walks or escalators that eliminate, or minimise so far as is reasonably practicable, the risks due to a missing pallet/step in moving walks and escalators. It is to be noted that compliance with technical standards alone may not ensure compliance with the duty.

- Ensure the design of any missing step device can effectively stop the moving walk or escalator before the gap emerges from the comb and a member of the public is exposed to the associated risk. The location needs to consider positions which minimises the likelihood of step or pallet falling off after passing the detection device.

- Review the models of moving walks and escalators you import, supply, or install to ensure compliance with the current version of the technical standard referenced in the design registration. If alterations to a registered design are required, it may be necessary to register the altered design with the state, territory or commonwealth regulator who registered the original design.

- Ensure current relevant information is provided, so far as reasonably practicable, to persons who, construct, install, commission, or use the moving walk or escalator.

There is no regulatory requirement to update the design registration of plant to the latest version of the technical standard stated. However, the duties in the WHS Act, require that any plant when supplied is, so far as is reasonably practicable, without risks to health and safety of persons. Technical standards for the design or safe use of plant may be considered information that “ought reasonably be known” to contain information about eliminating or minimising risk. If the technical standard is updated to include additional features to eliminate or minimise risk you may need to review any risk assessments for the design of the moving walks or escalators you import or supply.

Further information

Further information can be obtained from the following:

- Guide to the Work Health and Safety Act 2011 (PDF, 0.35 MB)

- Confirm if an incident is notifiable

- Notify us of an incident

- Managing risks of plant in the workplace code of practice 2021 (PDF, 1.57 MB)

- How to manage work health and safety risks code of practice 2021 (PDF, 0.65 MB)

- Safe Work Australia Guidance material for the safe design, manufacture, import and supply of plant

- Safe Work Australia Incident notification information sheet

- AS 1735.5.1 Lifts, Escalators and moving walks Part 5.1: Safety of escalators and moving walks – Construction and installation

- AS 1735.5.2 Lifts, escalators and moving walks Part 5.2: Safety of escalators and moving walks – Rules for the improvement of safety of existing escalators and moving walks