Mobile concrete placing boom stability

Issued: 17/11/2020

Last Updated: 17/11/2020

Purpose

The purpose of this safety alert is to:

- highlight the need to follow the manufacturer’s operating instructions

- provide safety guidance for workers, owners and employers.

Manufacturers and suppliers must ensure that mobile concrete placing booms are designed to be stable when used in accordance with their operating instructions.

Background

On 31 August 2020, a 37-metre mobile concrete placing boom became unstable while the operator was unfolding the boom. The truck cabin lifted off the ground with the unit balancing on its rear outriggers (refer Photograph 1). At the time of the incident, the boom’s hopper and pipeline were filled with concrete.

Photograph 1: Unit pivoting on rear outrigger feet.

Contributing factors

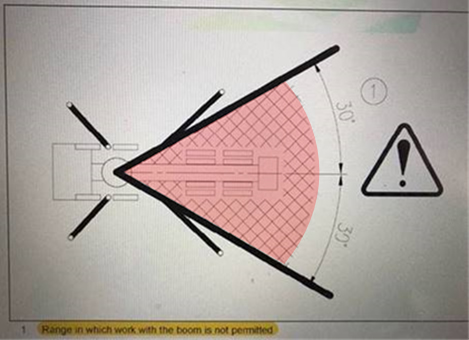

The initial investigation indicates the mobile placing boom was being operated outside of the manufacturer’s operating instructions. The manufacturer’s instructions stated the boom was not permitted to be operated in the range extending 30 degrees either side of the hopper (the restricted operating zone - refer Diagram 1). It appears the unit was unfolded within this restricted operating zone. The boom was not fitted with a device to prevent it being moved into the restricted operating zone. However, other contributing factors may be identified as the investigation continues.

At the time of the incident, the carrier was set up at a small operating angle that appeared to be within the maximum operating ground angle of 3 degrees specified in the operating manual.

Diagram 1 – Restricted operating zone for the unit involved in this event (highlighted in red).

Action required

Setting up a mobile concrete placing boom

When setting up a mobile concrete placing boom, operators should ensure the area is level to within the manufacturer's specifications, capable of supporting the load and free of obstructions. Operators should refer to the Concrete Pumping Code of Practice 2019 (PDF, 1.04 MB) for further information about items that require careful attention when setting up a mobile concrete placing boom.

Operating a mobile concrete placing boom

Different makes and models of mobile placing booms have different operating restrictions. As seen with this incident, booms are not always capable of being used through a full 360 degrees. While some of these mobile concrete placing booms have systems to prevent the boom being used in restricted zones, these systems are not fool proof and do not replace the requirement for operators to be trained in, and familiar with the operating instructions. The permissible working zone of a boom is not always documented in the product brochure (e.g. range charts), however operators should be aware that it can be found in the operating manual.

Level indicators

All mobile concrete placing booms should be fitted with level indicators, one on each side of the unit. Level indicators provide the operator with accurate information about the level of the carrier and the maximum allowable operating angle. These indicators should measure the chassis angle in two directions—in line with the vehicle and at right angles to the vehicle.

Check level indicators daily for damage and if they are mounted on springs (refer Photograph 2), check that no foreign material has been wedged under the indicators. Level indicator accuracy should be checked for correct calibration at intervals not exceeding 12 months.

Photograph 2: Example of a multi directional level indicator mounted on springs.

Training

It is important owners and operators are familiar with the manufacturer’s operating manual. Section 19(3)(f) of the Work Health and Safety Act 2011 and section 39 of the Work Health and Safety Regulation 2011 require a person conducting a business or undertaking to provide, training and instruction to workers. Documented familiarisation training should be provided to all operators for each make and model of mobile concrete placing boom they are required to operate. It is preferable that the training is broken up into a checklist and is more than a generalised statement that an operator has read and understood the operating manual.

At a minimum, training should include:

- ground type and minimum size of pads and dunnage under outrigger feet

- maximum allowable ground slope and carrier angle (the ground slope and carrier angle can differ depending on how the outrigger rams are deployed)

- allowable operating range of the boom both for deployment and operation

- method of unfolding and folding boom (on some booms it is possible to damage the boom if it is folded or unfolded incorrectly)

- safety precautions that must be followed where short-legging is permitted by the manufacturer

- pump and hopper operation

- pipeline and clamp inspection

- safe methods of cleaning the hopper and lines

- how to carry out a daily inspection of the plant

- precautions before and during road travel.

Stability testing of mobile concrete placing booms

Australian Standard AS 1418.15 – 1994 Cranes (including hoists and winches) Concrete placing equipment sets out stability benchmarks for mobile concrete placing booms. Importers and suppliers of mobile concrete placing booms should carry out stability testing in accordance with AS 1418.15. This should be completed for every combination of carrier on which a boom is mounted. The testing should be conducted in the least stable position within the permissible working zone.