Plate clamps and dropping loads

Issued: 22 May 2014

Last Updated: 22 May 2014

Purpose

The purpose of this safety alert is to highlight the risks associated with plate clamps used to lift loads, and to provide guidance on ways to use plate clamps safely.

Background

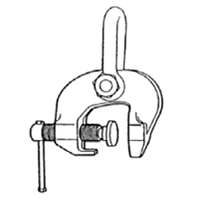

A worker's foot was severely injured when a section of plate steel fell from a plate clamp being used to lift a load. The type of clamp being used had a screw bolt (see diagram 1) and a steel bar to apply the clamping force.

All plate clamps are friction type lifting devices - meaning they are not positive lifting devices such as a latched hook through a lifting shackle. If the friction is inadequate either because the clamping force is too light, or the load knocks into something, the load can be released and drop without warning.

There are generally two types of plate clamp used in industry:

- Screw bolt: Where the clamping force is applied by a screw action (diagram 1)

- Lever: Where the clamping force is provided by a lever action, and is determined by the mass of the load (diagram 2).

Some plate clamps are intended for lifting horizontal plates only (diagram 3).

|  |  |

Diagram 1 - Plate clamp screw bolt | Diagram 2 - Typical lever plate clamp | Diagram 3 - Plate clamp for lifting horizontal plate |

Action required

Plate clamps are more prone to dropping loads than positive lifting systems. The use of positive lifting systems (e.g. a latched hook that passes through a hole in the steel plate) should be considered before using plate clamps.

Where alternative lifting systems are not practicable and plate clamps are used:

- never use damaged plate clamps

- never drag loads using with a plate clamp across the floor

- never lift loads using a plate clamp over a person or part of their body

- never lift loads with a plate clamp beside a person, where the load could hit the person if it released and fell sideways.

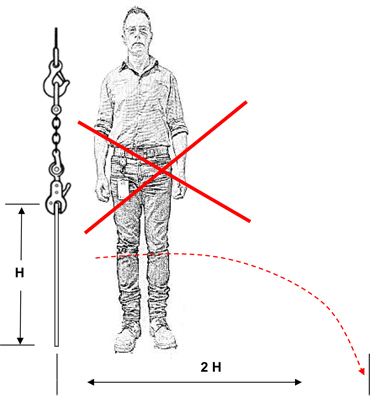

It is important that you stay away from the plate by a total distance of two times the height of the plate (see diagram below). This takes into consideration the plate height plus a safety margin to allow for plate bounce.

Diagram 4 - Never allow the worker to stand too close to the load.

Make sure:

- workers are provided with adequate information, training, instruction and supervision in the use of plate clamps

- the lifting system has been approved by a competent person (such as a dogger, rigger or engineer)

- the plate clamp is suitable for the load to be lifted (consider plate thickness, mass, hardness and surface condition)

- a screw type clamp is tightened to the manufacturer's specifications (e.g. with a torque wrench)

- the correct number of plate clamps are used to lift long loads, and noting the angle of the clamp must not exceed the manufacturer's instructions

- the plate clamp shackle cannot come off the lifting hook when lowering a plate.

Further information

- How to manage work health and safety risks Code of Practice 2021 (PDF, 0.65 MB)

- Managing the risks of plant in the workplace Code of Practice 2021 (PDF, 1.57 MB)

- Mobile crane Code of Practice 2024 (PDF, 2.29 MB)