Falling object from tower crane

In July 2021, WHSQ was advised of a tower crane incident where a climbing frame guide roller assembly, four bolts and two shim plates fell to the ground.

These findings are not yet confirmed and investigations are continuing into the exact cause.

Safety issues

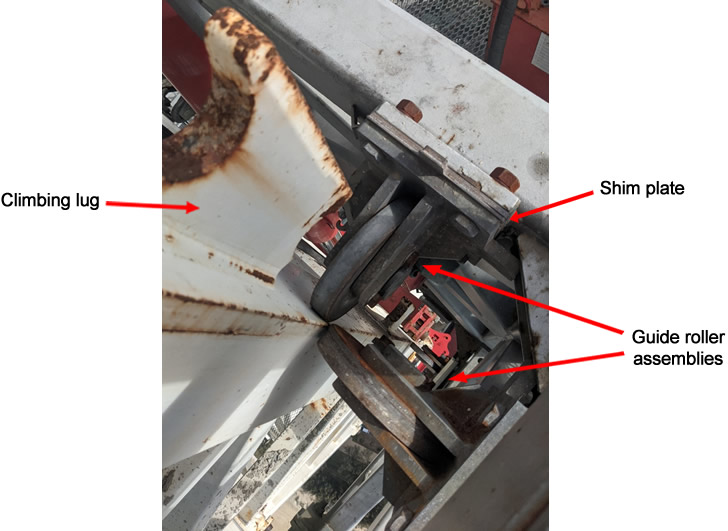

In this incident, the climbing system incorporated two climbing lugs on the outside of the tower. As the tower was raised, the lugs would move past guide rollers on the inside corner of the climbing frame (see Figure 1). Early investigations indicate the guide roller assembly contacted a climbing lug and the four bolts attaching the assembly to the climbing frame were sheared off. This caused the roller assembly along with the broken bolts and two shim plates to fall 62 storeys to the ground. Thankfully, no one was injured as a result of this incident, however the risk to workers and others was significant. The roller assembly alone weighed more than 20 Kg.

Ways to manage health and safety

Taking steps to manage risks is a condition of doing business in Queensland. Effective risk management starts with a commitment to health and safety from those who manage the business. If an incident occurs, you'll need to show the regulator you’ve used an effective risk management process. This responsibility is covered by your primary duty of care in the Work Health and Safety Act 2011.

Use the hierarchy of controls to help decide how to eliminate and reduce risks in your place of work. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. It’s a step-by-step approach to eliminating or reducing risks. You must work through the hierarchy of controls when managing risks, with the aim of eliminating the hazard, which is the most effective control.

Overview of externally fitted climbing frames

Climbing frames are used on tower cranes so the crane can self-climb without using another crane. Climbing frames have been used for many years, especially on high rise jobs where it is impractical for a mobile crane to erect the tower crane to its full height. While climbing frames can be used on different types of tower cranes, they are more frequently used on luffing type tower cranes where the boom is capable of pivoting.

The climbing frame is installed around the mast of the tower crane and incorporates one or more double acting hydraulic cylinders to raise the top of the crane so new mast sections can be inserted and pinned or bolted in place. The frame is largely open at the front to permit the passage of the new mast section. For convenience, the description given below is for climbing frames fitted with a single hydraulic cylinder.

The climbing frame is connected to the top of the crane below the slewing module, upon which the crane rotates. The base of the hydraulic cylinder assembly is positioned on the mast of the crane and pushes against special climbing lugs on the mast. The top of the crane, including the slewing module, main jib, machine deck together with counterweights and crane cab, is then disconnected from the mast and the hydraulic cylinder ram is used to raise it a sufficient distance in order to insert a new mast section, increasing the crane height.

The frame incorporates sets of guide rollers or wheels which act on the faces or corners of the crane mast and restrain lateral movement during climbing. The guide rollers or wheels and the crane mast will generally resist any overturning forces developed during a climbing operation.

The rollers or wheels are intended to keep the top of the crane vertically aligned during the climbing process.

The hydraulic cylinder(s) on climbing frames are extremely powerful as they have to support the dead weight of the tower crane above the frame. If a climbing frame roller assembly snags on an obstruction, such as a jacking lug on the tower, the hydraulic power can easily break the assembly off and create a falling object risk. As a climbing frame can be at a significant height above ground level, the falling object may land many metres from the base of the tower crane and poses a significant risk to workers and members of the public.

Possible control measures to prevent similar incidents

This incident has highlighted the risk of falling objects during climbing operations. Climbing tower cranes is a complex activity that requires a highly competent rigging crew with specialised training. To help address the risk of falling objects during tower crane climbing operations, section 5.4.1 of the Tower Crane Code of Practice (PDF, 1.56 MB) (the Code) specifies an exclusion zone of at least a 12m radius from the base of the tower crane to help reduce the risk from falling objects. However, this exclusion zone should not be relied on to adequately address the risk of falling objects. If an object falls from height, it can fall well outside of a 12m exclusion zone. It is therefore a much better alternative to implement systems that reduce the likelihood of an object falling in the first place. Ways to achieve this include the following:

- Making sure the climbing frame is positioned so that the clearances between the guide roller assemblies and tower section or climbing lugs specified by the manufacturer are complied with. This will require using the correct number of shims or packers under each roller assembly.

- Ensuring the sizes and locations of climbing lugs on tower sections comply with the manufacturer’s dimensions and tolerances (to achieve this the dimensions should be checked when the tower sections are in the crane yard against the manufacturer’s design drawings).

- Being aware that as a tower crane becomes higher, the tower will become more prone to swaying (e.g., from wind) and the relative movement between the tower and climbing frame may increase. This may increase the risk of the climbing lugs hitting the guide rollers as the climbing cylinder raises the crane.

- On climbing frames where there is a risk of the guide roller assembly hitting climbing lugs on a tower (i.e., lugs protrude from the tower) - use a spotter(s) so that climbing can stop before damage occurs. Each spotter should have clear communication with the rigger operating the climbing cylinder.

Note: Section 5.4.4. of the Code discusses the use of restraining systems on packers or shims to catch the component if it inadvertently dropped (i.e., safety chains). This method is frequently used for packers where the tower is tied back to a building. However, on a climbing frame, the packers may need to be moved between roller assemblies and a safety chain could potentially introduce other hazards. The method could, however, be used as a temporary back up to use on a packer while a rigger is trying to position the packer in place (i.e., while the bolts are being inserted). However, the slack in a safety chain must be minimised and there must be no risk of the chain failing from shock loading if the packer falls.

More information

- How to manage work health and safety risks code of practice 2021 (PDF, 0.65 MB)

- Tower crane Code of Practice 2017 (PDF, 1.56 MB)

- Tower crane checklist (DOCX, 0.04 MB)

- Guide to inspecting and maintaining cranes – Safe Work Australia

- Safe Work Australia – Guide to Tower Cranes

- HSE Discussion paper on the safe use of ‘external’ climbing frames on tower cranes(PDF)

Support for people affected by a serious workplace incident

For advice and support: