Worker killed after tyre explosion

In September, a truck driver was killed while inflating a tyre. Initial indications are the transport firm employee sustained fatal injuries when the tyre he was inflating exploded.

Investigations are continuing.

Preventing a similar incident

Inflated tyres, particularly truck tyres, contain a large amount of stored energy. Tyres are designed to withstand this, but if they are damaged or have been used while flat (or significantly underinflated), they may fail. Tyre damage due to underinflation cannot always be detected by external inspection. If a tyre fails during inflation, the explosive force can be released resulting in a destructive air blast and the ejection of high-speed particles. If the wheel is not restrained, it can fly through the air. The rapid release of this explosive force from a ruptured tyre can result in serious injuries or even death.

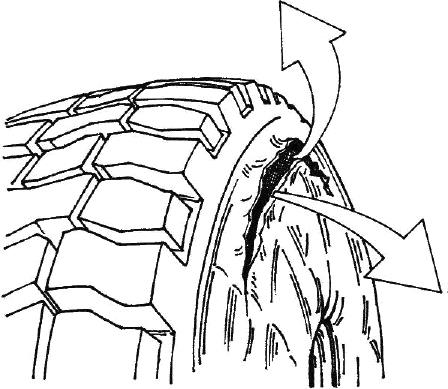

Figure 1 – An example of a failure in the side wall of a tyre commonly known as a zipper failure

Health and safety risks must be managed to eliminate danger. However, if it's not reasonably practicable to eliminate the risk, then it should be minimised using the hierarchy of controls. This can be achieved by doing one or more of the following:

- Substituting the hazard with one that is of lesser risk – for example, if a truck tyre has been identified as underinflated while in use, do not immediately re-inflate the tyre in-situ. Instead, fully deflate the tyre and replace the wheel with a spare and have the tyre inspected by a competent person to determine if it is safe to put back into service.

- Isolating the hazard from workers:

- deflating tyres prior to them being removed from the machinery or vehicle and inflating tyres in a safety cage or other portable restraint device.

- never reach into the cage during inflation or deflation and always position the body to one side of it.

- deflating tyres prior to them being removed from the machinery or vehicle and inflating tyres in a safety cage or other portable restraint device.

- Implementing engineering controls - for example, by fitting:

- a long enough air hose with a clip-on valve nozzle and remote pressure gauge for workers to stay outside of an exclusion zone (i.e. the potential trajectory or explosion zone), and

- a remote dump valve that is capable of rapidly deflating the tyre in an emergency.

Any remaining risk must then be minimised by using administrative controls. For example:

- have a regular tyre maintenance schedule which checks tyres for condition, matching, pressure, tread depth and wear patterns, as well as rims for corrosion or cracking

- always follow the recommended tyre servicing procedures and ensure all workers undertaking these procedures are trained and follow them

- inform, train and supervise staff in safe personal positioning and safe procedures during tyre inflation including actions when a potential tyre failure is identified

- potential trajectory paths from a failure and exclusion zones have been identified

- the wheel is inspected for damage and corrosion prior to the refitting of tyres

- tyres (new or used) are inspected for defects

- workers stand outside of any exclusion zones

- tyres are only inflated to the recommended pressure

- all safety cages, air-lines and associated equipment are suitable for the task and maintained in a safe working condition.

If a residual risk remains, it must be minimised so far as reasonably practicable by using personal protective equipment (PPE). For example, wearing protective goggles or face shields when working on wheels or tyres.

Administrative control measures and PPE rely on human behaviour and supervision and used on their own tend to be least effective in minimising risks.

SAFE TYRE INFLATION

- DON'T lean over the assembly during inflation

- DON'T sit or stand near the assembly

- DO use a clip-on chuck to connect the airline with a quick release valve (i.e. dump valve) at the operator's end (this allows tyre deflation from a safe distance if problems occur)

- DO ensure the airline hose is long enough to allow the operator to stay outside the likely explosion trajectory during inflation

- DO use enough bead lubricant when seating the tyre

- DON'T use valve connectors that require the operator to hold them in place

- DON'T exceed the manufacturer's recommended tyre pressure for the size and rating of the tyre

- DON'T use airlines not fitted with either a pressure gauge or pressure control device

- DON'T allow the control valve to be jammed open (which would allow the operator to leave the inflating tyre unattended).

This should ensure the operator is clear from any blast.

Statistics

On average each year there are 36 workers' compensation claims accepted for injuries relating to being hit or trapped or by an explosion involving vehicle wheels and tyres.

From 2013 to May 2019, WHSQ has been notified of 23 events involving exploding tyres and issued seven statutory notices relating to the risk of tyre explosions.

Prosecutions and compliance

In 2014, a company accepted an enforceable undertaking with a total minimum expenditure of $207,401 as an alternative to prosecution. This was after a worker received serious facial fractures and another minor leg injuries when they attempted to fit and inflate a tyre to a damaged truck rim. The tyre exploded as it was being inflated.

More Information

- How to manage work health and safety risks code of practice 2021 (PDF, 0.65 MB)

- Managing risks of plant in the workplace code of practice 2021 (PDF, 1.57 MB)

- Workplace hazard - Safety with tyre fitting

- Australian Tyre Industry Council Ltd Advisory Bulletin 3

- Tyre removal, replacement and inflation

- US Tire Information Service Bulletin Vol. 33 No. 5

Support for people affected by a serious workplace incident

Have you been affected by a workplace fatality, illness or serious injury? For advice and support, visit our Facebook page or email ohs.coronialliaison@oir.qld.gov.au.