Worker struck in head by portable hydraulic jack

In September 2017, a worker sustained serious head injuries while operating a portable hydraulically powered jack. He was using the jack to expand a semi-circular shaped metal bracket when it dislodged and struck him in the face. He was found unconscious sometime after the incident occurred.

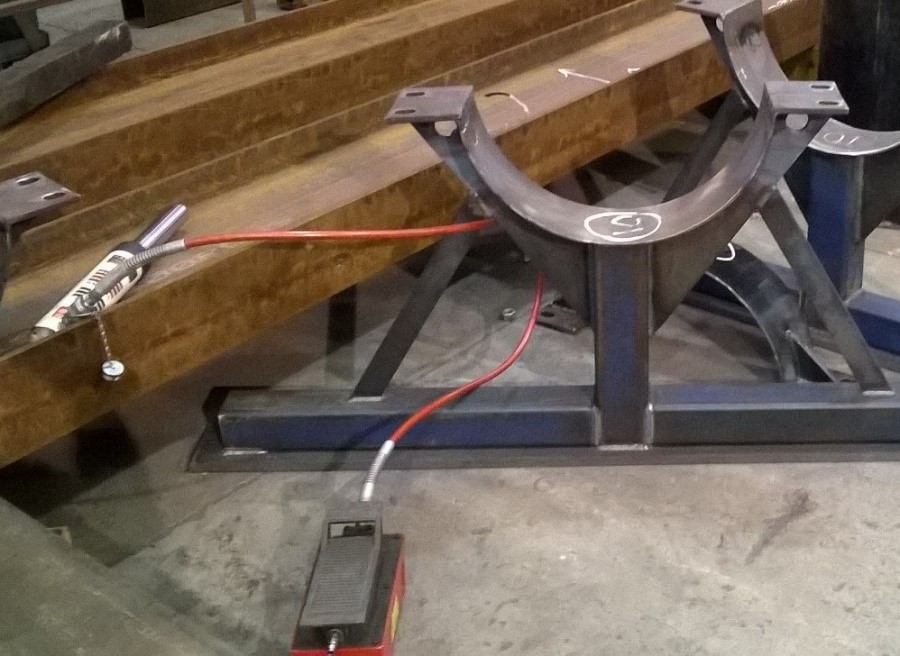

Initial inquiries indicate the jack was positioned between two curved surfaces of the metal bracket which did not provide a stable surface for it to operate on, and it dislodged while under pressure (see photo 1).

Photo 1: Shows portable power jack laying next fabricated metal bracket

This alert is a reminder that the incorrect use or operation of hydraulic equipment under pressure can be extremely dangerous.

Preventing a similar incident

When using portable power jacks or cylinders:

- ensure it is a suitable tool for the job being carried out

- always use it in accordance with manufacturer's instructions

- ensure that the entire base of the jack is on a hard, flat surface

- ensure that a saddle is fitted to the end of the ram

- ensure the entire saddle is in contact with the load

- ensure the movement of the cylinder is parallel with the movement of the load

- avoid standing in the same line of movement or in close proximity to the jack

- ensure a safe system of work is in place and is followed

- apply the pressure slowly and check the load often.

It is important to note that load lifting and shifting equipment such as hydraulic jacks or spreaders, are not intended to hold a load in place. Once a load is in its desired position, the load must be supported (for example with a back-up prop) should the hydraulics fail. Never work under or between unsupported loads.

Persons conducting a business or undertaking (PCBU's) must ensure that workers are suitably trained and are competent to operate this type of plant.

PCBU's must also manage the risks associated with workers carrying out work in isolation. A worker may be considered to be working in isolation even if there are other people nearby, e.g. a worker carrying out unsupervised work activities in an obscured corner of a factory. PCBU's must ensure that workers carrying out activities in isolation are adequately monitored and supervised.

Statistics

Over the last 5 years, 87 workers' compensation claims have been accepted relating to hydraulic plant. 15 were for serious injuries.

Since July 2016, Workplace Health and Safety Queensland (WHSQ) has been notified of 45 incidents involving hydraulic failure. Of these, 24 resulted in injuries requiring either hospitalisation or medical treatment and two involved portable power jacks.

Since 1 July 2016, WHSQ has issued 11 notices (seven improvement and four prohibition) for failure to ensure proper use of plant, and six improvement notices for failure to ensure safe systems of work relating to isolated work. Both of these factors contributed to this hydraulic incident.

Prosecutions and compliance

In March 2017, a Coopers Plains company was fined $125,000 following the death of a worker. The worker was helping to remove a gas strut from a prototype boat rack on a trailer when it exploded, striking him above his right eye and penetrating his skull. Investigations revealed that the company had not developed a safe system of work for manufacturing and fabricating the boat rack and that a risk assessment had not been conducted for installing the struts.

Workplace Health and Safety Queensland also investigated a July 2017 incident involving a portable power jack. A worker had a finger de-gloved and lacerated while trying to push out an eye-bolt using a portable power jack on an LPG tanker. The PCBU took immediate steps to prevent the incident re-occurring and no further enforcement action was taken.

Support for people affected by a serious workplace incident

Have you been affected by a workplace fatality, illness or serious injury? For advice and support, visit our Facebook page or email ohs.coronialliaison@oir.qld.gov.au.