Mobile and tower crane hoist limits

Issued: 4/3/2022

Last Updated: 4/3/2022

The purpose of this safety alert is to highlight the risk of hoist rope failure and loads dropping from mobile and tower cranes, which can occur when the hoist limit is disabled or does not function correctly. Employers, builders, workers and crane operators should apply the principles in this alert to any crane with a hoist rope.

Background

Hoist limits stop the hook block before damage to the crane can occur (i.e. ‘two blocking’ cannot occur). Hoist limits in the mobile crane industry are typically known as anti-two block devices. On most mobile cranes, the hoist limit generally includes a small weight hanging from chain(s) hooked up to a limit switch (refer Photograph 1). As soon as the upward motion of the hook block hits this weight, a switch is activated and some crane functions are disabled (e.g. hoist up, tele out and boom down).

On many tower cranes, the hoist limit is based on a geared device attached to the hoist rope drum that activates a deceleration device (‘decel limit’) and a final limit. The decel limit slows the hoisting speed from high speed to low speed1 and the final limit stops the hoisting function. On tower cranes there will usually be some variation between the points where the decel and final limit activate on the same crane. This is due to characteristics of the cam device connected to the rope drum drive (the drive reduction from the rope drum to the cam spindle is significant).

Irrespective of the type of crane and hoist limit device, correct operation of the hoist limit is important to avoid major safety issues.

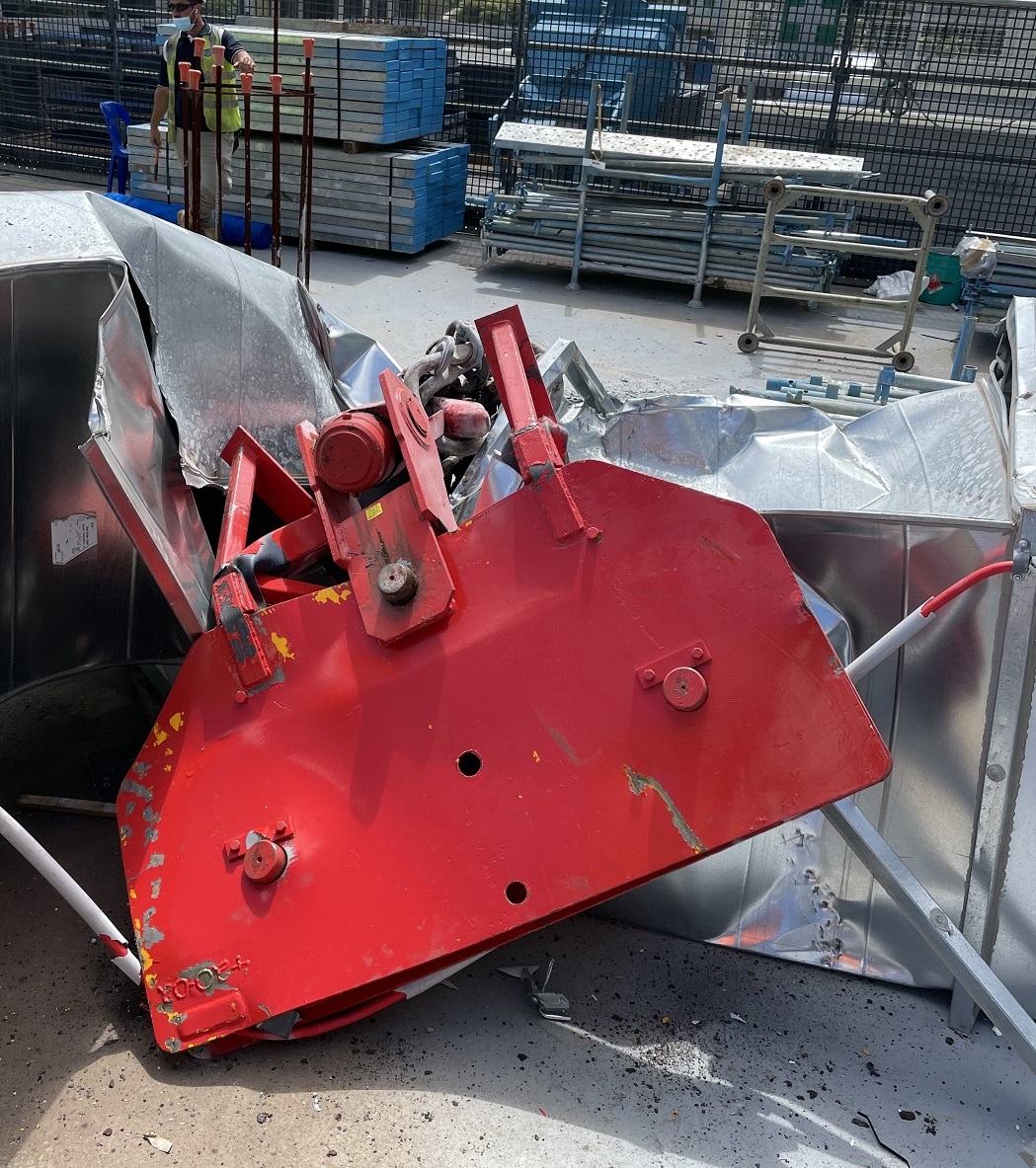

In the last three years there have been four incidents where hook blocks have fallen due to the hoist limit not functioning as intended. In three tower crane incidents the hoist rope broke, dropping a heavy hook block from the crane boom. In the 2019 incident involving a hammerhead tower crane rigged with two falls of rope, the hook block and the load of scaffold stair modules fell approximately 40 metres and hit the ground very close to a pedestrian and a worker (refer Photograph 2). In the January and February 2022 incidents, involving electric luffing tower cranes, the hook block, rigged with two falls of rope, fell from the boom tip to a suspended slab more than 50 metres below and an adjoining property 100 metres below respectively. In the January 2022 incident, the hook block punched a hole in the top of the slab2 and then bounced onto an airconditioning duct, causing substantial damage (refer Photograph 3). In the February 2022 incident the hook block struck the perimeter screen on the site and two counterweights bolted to the side of the hook block became detached as the hook block dropped. A rope sheave was also destroyed with parts of the sheave falling to the ground. The hook blocks in these two incidents weighed approximately 400 kilograms.

Photograph 1: Anti-two block weights on a mobile crane (indicated by arrows).

Photograph 2: Hook block on load of scaffold stairs - 2019 incident.

The December 2021 incident involved a 130 tonne maximum rated capacity hydraulic boom slewing mobile crane, rigged in single fall. The hook block was pulled through the rope keeper bar(s) and over the head sheaves while being hoisted up before falling onto the deck of the crane causing significant damage (refer Photograph 4).

Contributing factors

In the 2019 hammerhead tower crane incident, the hoist limit had been disabled so that loads could be lifted higher. When the crane was initially installed, it was not erected so that the boom was high enough above the top floor of the building under construction. Although the crane operator had been made aware the hoist limit had been disabled, he was unable to prevent the hook block contacting the trolley. Both the decel and final limits had been disabled, so the crane operator was not prevented from hoisting all the way up at high speed.

In the December 2021 mobile crane incident, it is understood the anti-two block malfunctioned and the hook block was able to run over the boom tip of the crane. The reasons why the anti-two block malfunctioned have not been determined.

In the January 2022 luffing tower crane incident, a check of the winch drum after the incident indicated a decel and final limit were working. However, the distances at which these limits were set could not be accurately verified as the hoist rope was broken. Inspection of the boom following the incident confirmed the rope had failed due to two blocking, so it is possible that, although the limits were operating, they were inadequate. In the February 2022 incident, it is understood the hoist limits had been operating prior to the incident.

In both of the luffing tower crane incidents, the crane was being packed up with the boom luffed up to a relatively high angle. It appears the crane operators initially raised the boom then hoisted up. With a high boom angle, it can be difficult for an operator to see the amount of hoist rope between the boom tip and the hook block.

Photograph 3: Damaged air-conditioning duct from dropped hook block - January 2022 incident.

Photograph 4: Damage to 130 tonne mobile crane from dropped hook block - December 2021 incident.

Action required

Any hoist limit system set up on a mobile or tower crane should ensure two blocking cannot occur, irrespective of the hoist speed, the number of rope falls or the boom luff angle.

The lower the number of rope falls between the hook block and the boom (e.g. head sheaves, hook trolley), the faster the hook block will approach the boom. For example, in single fall the hook block will approach the boom four times faster than a crane with four falls of rope based on the same winching speed. Therefore, setting limits based on distance below the boom and using this same distance irrespective of the number of rope falls may not be adequate. As an example, setting a final limit based on a vertical distance that will guarantee two blocking does not occur for four falls may not be effective for less than four rope falls.

Preventing two blocking

- Hoist limits should be set up in accordance with the crane manufacturer’s instructions.

- All safety features provided by the crane manufacturer, including the hoist limit, must remain operational and are not to be overridden for normal operation of the crane.

- For hoist limits to be effective they need to take account the potential variation between subsequent applications of the hoist limits (e.g. if the final limit on the hoist can have a possible variation of one metre and the crane manufacturer specifies the final limit needs to operate at one metre below the head sheaves, the limit may need to be set at two metres or more).

- On some cranes the distance between the head sheaves and hook block will vary depending on the boom angle. On these cranes, that also have the host limit connected to the rope drum, the hoist limit should be set at the crane boom angle where the hook block will be closest to the head sheaves.

- The only legitimate reason for temporarily overriding the hoist limit switch is for rigging purposes, including when the crane is commissioned, dismantled or the rigging set up on the hook block is being changed (e.g. some tower cranes can be changed from two to four rope falls).

- If two blocking occurs, even when the crane manufacturer’s instructions on setting the hoist limits are followed, the crane manufacturer should be notified, and steps taken to ensure the hoist limit is adjusted so two blocking will not occur. The crane should be inspected by a competent person prior to returning to service.

- When selecting the tower crane for a particular site, it is important the hook height is high enough to carry out all lifting activities without the need to override the crane’s safety features.

- Irrespective of safety devices on a crane, the crane should be operated in accordance with the manufacturer’s instructions.

- When packing up luffing tower cranes at the end of a shift, the hook should be hoisted up before raising the boom so that the operator has clear sight of the hoist rope between the hook block and the boom tip.

- During the daily inspection, the hoist limit switch should be checked to confirm it is functioning correctly before attaching a load to the hook.

Further information

Further information can be obtained from the following:

- Tower Crane Code of Practice 2017 (PDF, 1.56 MB)

- Mobile Crane Code of Practice 2006 (PDF, 1.34 MB)

- Some tower cranes have two decel limits and then a final limit.

- The hook block did not penetrate through the deck most likely due to the use of sacrificial metal formwork on the underside of the deck.