Excavator bucket strikes construction worker

In November 2022 a worker was seriously injured when he was struck by an excavator bucket at a construction site. Initial enquiries indicate the excavator was operating near the worker when, for reasons yet to be established, its bucket unexpectedly detached from a quick-hitch on the dipper arm, striking him.

These findings are not yet confirmed, and investigations are continuing into the exact cause.

Safety issues

Operating powered mobile plant at construction sites exposes workers to health and safety risks, including:

- the plant overturning

- things falling on the operator

- the operator being ejected from the plant

- the plant colliding or coming into contact with workers, other vehicles or plant, energised powerlines and other things

- mechanical or other failures such as hydraulic failures and release of hazardous substances.

A quick-hitch (also known as a quick coupler) is a latching device which enables attachments to be rapidly connected to or disconnected from plant. Quick-hitches are commonly fitted to earthmoving plant (e.g. attached to the dipper arm of an excavator) and there are different types available. While these devices save time and effort compared to changing attachments that are directly coupled to the plant, people have been killed in Australia when attachments have fallen off the quick-hitch due to loss of hydraulic pressure.

Other factors contributing to these kind of incidents include workers being in the vicinity of operating plant (i.e. within an exclusion zone), and operators having restricted visibility of ground workers or nearby pedestrians, particularly those close to the plant around blind spots.

Ways to manage health and safety

Taking steps to manage risks is a condition of doing business in Queensland. Effective risk management starts with a commitment to health and safety from those who manage the business. If an incident occurs, you'll need to show the regulator you’ve used an effective risk management process. This responsibility is covered by your primary duty of care in the Work Health and Safety Act 2011.

Use the hierarchy of controls to help decide how to eliminate and reduce workplace risks. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. It’s a step-by-step approach to eliminating or reducing risks. You must work through the hierarchy of controls when managing risks, with the aim of eliminating the hazard, which is the most effective control.

Possible control measures to prevent similar incidents

There are significant risks associated with using mobile plant fitted with quick-hitches. Persons conducting a business or undertaking (PCBUs) must eliminate risks arising from mobile plant in the workplace, or if that is not reasonably practicable, minimise the risks. Specific controls are required for mobile plant under the Work Health and Safety Regulation 2011.

Before operating any piece of mobile plant, the person with management or control must ensure:

- a suitable combination of operator protective devices for the plant is provided, maintained and used so far as is reasonably practicable

- the plant, or part of the plant (i.e. attachments) does not collide with pedestrians or other powered mobile plant

- where there is a risk of collision, that the plant has a warning device to warn other persons of the risk.

Some common risk control measures can include but are not limited to the following examples.

Specific controls

Controls to consider for excavators fitted with quick-hitches:

- Provide excavators fitted with fully automatic quick hitches, which don’t require the operator to insert a safety pin to prevent the quick hitch releasing.

- Ensure that where fully automatic quick hitches are not provided safety pins are always used.

- Ensure all quick hitch attachments have the original equipment manufacturer’s safety system.

Source: Safe use of quick hitches on excavators Alert - Resources Safety & Health Queensland

- Quick-hitches should comply with the safety system specifications included in AS 4772 Earthmoving machinery – Quickhitches for excavators and backhoe loaders. If the quick-hitch does not comply with AS 4772, it is to be fitted with a manual locking pin.

- If the quick-hitch supplier claims a quick-hitch complies with AS 4772, a certification document stating this should be provided by the supplier upon request.

Developing a safe system of work

A safe system of work should be implemented to manage the risks associated with mobile plant and associated attachments. This could include, but is not limited to:

- ensuring the plant and attachments are selected, used, inspected, maintained and repaired according to the manufacturer’s recommendations and specifications. This includes ensuring the attachment pin centres and pin diameters are within the dimensions and wear tolerances specified for the particular quick-hitch. Using attachments with incorrect pin diameters and centres may cause the safety system of a quick-hitch to be ineffective.

- ensuring the manufacturer's instructions are included in a safe work procedure on how inspection and maintenance should be carried out. For example, checking if the plant or equipment show any signs of excessive wear, damage or cracks to structural components such as excavator dipper arms and plant attachment points

- plant operators conducting daily pre-start checks on the general condition and maintenance of the plant, including the quick-hitch assembly

- the safety system only allowing attachments to be disconnected from the quick hitch by intentional means, so unintentional disengagement is prevented.

- ensuring the operator has received adequate training and instruction in the use of the plant:

- PCBUs should assess and verify the operator’s knowledge and competence to operate the plant before they commence work. This includes selecting compatible attachments, verifying correct engagement of the primary and secondary (safety) retention systems and identifying any faults or malfunction of the quick-hitch’s safety system

- operators should be able to demonstrate they are competent to operate the specific type of plant being used and attachments fitted to the plant, including the specific make and model of quick-hitch mechanism

- ensure records are kept of operators demonstrating the safe fitting of attachments prior to operating plant (Source: Safe use of quick hitches on excavators Alert)

- training should include requirements for ensuring that the quick-hitch safety mechanism remains effective. (For example, inspection and measuring of wear and tolerance in accordance with the manufacturer’s instructions)

- in some circumstances, the mobile plant operator may also need to hold the right high risk work licence.

Pedestrians, powered mobile plant and blind spots

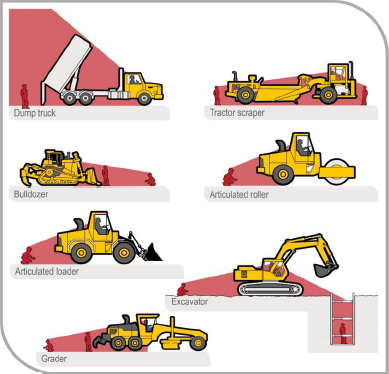

Plant operators and ground workers should be made familiar with the blind spots of the plant being used. Figure 1 shows several blind spots for typical mobile plant.

Figure 1: Blind spots of typical mobile plant

Source: WHSQ - Excavation work code of practice 2021

Your safe system of work should also consider the following examples regarding mobile plant and blind spots:

- develop induction training programs that emphasise the dangers of people working near mobile plant

- ensure all relevant information, training, instruction and supervision is provided before work begins

- consider operational exclusion zones:

- exclusion zones should take into account the type of work being performed and the particular movement of the plant. For example, with excavator slewing, workers are at risk from the dipper arm and the bucket, as well as the counterweight

- minimise the need for workers to be inside exclusion zones while the plant is operating. Determine if the worker can do their job outside of the exclusion zone, at another time, or when the plant is inactive

- use physical barriers that prevent workers or plant access to designated areas, such as fencing, para-webbing or water filled barriers.

- before work starts, develop an effective system of communication (e.g. two-way radios and hand signals) should be established based on two-way acknowledgement between mobile plant operators and ground workers:

- workers should also be trained in the safe work procedures involved prior to the work commencing

- the system should stop ground workers from approaching mobile plant until the operator has agreed to their request to approach

- similarly, the system should stop operators from moving plant closer than a set distance from ground workers until the operator has been advised by ground workers, they are aware of the proposed movement.

- before allowing workers to enter a hazardous zone (e.g. within the slew radius of the excavator), the dipper arm should be lowered and the machine turned off or the controls disengaged to prevent inadvertent activation of the controls.

Any remaining risk must be minimised with suitable personal protective equipment (PPE). For example, use of hard hats, steel cap boots, eye protection, hearing protection and high visibility vests.

Administrative control measures and PPE rely on human behaviour and supervision. If used on their own, they are least effective in minimising risks. The control measures you put in place should be reviewed regularly to make sure they work as planned.

More information

- Managing the risks of plant in the workplace Code of Practice 2021 (PDF, 1.57 MB)

- Mobile crane Code of Practice 2006 (PDF, 1.34 MB)

- Working in and around mobile plant – film

- Excavation work code of practice 2021 (PDF, 1.9 MB)

- Earthmoving Checklist - planning the safe set-up and operation of earthmoving equipment (DOCX, 0.03 MB)

- Safe use of quick hitches on excavators Alert - Resources Safety & Health Queensland

- Quick-Hitches For Earthmoving Machinery Information Sheet – Safe Work Australia

- AS 4772-2008: Earthmoving machinery- Quickhitches for excavators and backhoe loaders

Australian Standards can be obtained by contacting Standards Australia.

Have you been affected by a workplace fatality, illness or serious injury?

For advice and support: