Workers injured in formwork collapse

In June 2022, several concreters were injured after falling between three and four metres when a formwork deck collapsed at a construction site. Initial investigations indicate they were pouring a concrete slab for a mezzanine floor when for reasons yet to be established, the formwork system failed.

These findings are not yet confirmed, and investigations are continuing into the exact cause.

Safety issues

Formwork is a temporary structure used to contain and shape wet concrete until it is self-supporting. Once assembled the components form the temporary structure.

Formwork incidents can have serious consequences. Hazards associated with formwork erection, alteration or dismantling include:

- formwork collapse (before, during and after placement of concrete)

- falls from heights

- slips and trips

- falling objects

- dust.

Ways to manage health and safety

Taking steps to manage risks is a condition of doing business in Queensland. Effective risk management starts with a commitment to health and safety from those who manage the business. If an incident occurs, you'll need to show the regulator that you’ve used an effective risk management process. This responsibility is covered by your primary duty of care in the Work Health and Safety Act 2011.

Use the hierarchy of controls to help decide how to eliminate and reduce risks in your place of work. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. It’s a step-by-step approach to eliminating or reducing risks. You must work through the hierarchy of controls when managing risks, with the aim of eliminating the hazard, which is the most effective control.

Possible control measures to prevent similar incidents

A PCBU must eliminate risks so far as is reasonably practicable, and if it is not reasonably practicable to eliminate the risks, by minimising those risks so far as is reasonably practicable. It also includes ensuring, so far as is reasonably practicable the:

- design, provision and maintenance of safe formwork plant and structures

- safe erection, alteration, dismantling and use of formwork

- safe use, handling, storage and transport of formwork plant.

Eliminating hazards at the design or planning stage is often easier and more cost effective to achieve than making changes later when hazards become real risks in the workplace. Safe design means the integration of control measures early in the design process to eliminate or, if this is not reasonably practicable, minimise risks to health and safety throughout the life of the structure being designed.

Safe formwork design and certification

A suitably qualified civil engineer experienced in formwork design, is responsible for overseeing the safe design and certification of the complete formwork structure. This includes design of the formwork support structure, the formwork deck and connection details, and certification that the formwork drawings and other formwork documentation have been completed. When specifying the design of the formwork system, the engineer must allow for all loads that can be expected to be applied during construction, including loads applied by:

- the formwork deck, supporting members and formwork frames

- any false decks that may be provided

- concrete pouring techniques (i.e. kibble or pump)

- the concrete pour which includes both the weight of the concrete and dynamic factors applied. The concrete pour rate and pour sequence must be specified

- workers on the formwork deck and false decks

- stacked materials

- crane lifted materials on both the complete and incomplete formwork deck

- wind to the system as detailed in AS1170.2 Structural design actions - Wind actions. An allowance for wind loading is particularly important for vertical forms

- environmental loads including forces due to water flowing around the formwork. Rain and run off can have a detrimental effect if not considered by a designer.

Control measures for several other formwork issues

- Where floors to be poured are supported by welded steel brackets, the bracket design has adequate strength and the welding and material specifications comply with the design engineer’s instructions. Brackets need to be strong enough to support both floor dead loads and the maximum floor live loads when the building is completed and in use.

- Formwork documentation - all formwork documentation should be completed in accordance with the Formwork code of practice 2016 including:

- project and formwork engineer drawings, specifications and engineer certifications

- pre-pour inspections, formwork systems and associated components, and site erection methods

- engineer or competent person sign-offs.

- Modular proprietary formwork systems – these are intended to be erected in specific configurations as prescribed by the designer and manufacturer. Both modular and traditional formwork systems should be designed to comply with the loadings and general principles of AS3610: Formwork for Concrete.

- Materials - all materials and equipment used in formwork construction must be fit for the intended purpose and meet design specifications.

- Design of materials and equipment must conform to relevant Australian Standards and must also be manufactured in accordance with a quality assurance system that ensures compliance with the design specification.

- A suitable system must be implemented to ensure that only materials and components that comply with the specifications of the formwork design drawings and documentation are being used.

- Materials and components that are damaged, excessively worn or not fit for the intended use must not be used. This includes broken components, timbers with rot or excessive nail holes and components with missing parts.

- Entry and exit – clear access is important for the safe movement of materials, equipment and persons on site.

- Designated access ways must be provided.

- Emergency access and egress must be considered and provided to all parts of the workplace where persons are required to work. Two forms of emergency access and egress should be maintained at all times. Specific access requirements should be in place for slip and jump forms.

- Stretcher stairs should be the primary access to the formwork deck whenever it is possible.

- Consultation - workers and health and safety representatives are required to be consulted at each step of the risk management process. It is important to consult with workers as formwork activities progress. Where you share responsibility for a health and safety matter with other business operators who are involved in the same activities or who share the same workplace, you must exchange information to find out who is doing what and work together in a cooperative and coordinated way so that all risks are eliminated or minimised as far as reasonably practicable.

- Training of workers – workers should be provided with all relevant training, information and supervision relating to the system they are erecting, including specific training for formwork systems. Such training and information should include but not limited to:

- the formwork system, tasks, activities and components

- the way the manufacturer or designer of the formwork system intended the system to be erected, installed, used, moved, altered or dismantled

- specific training and information required to undertake or participate in specific tasks or activities

- safe working procedures, including the use of mechanical aids and devices, where appropriate

- how to use and maintain equipment, including any specific conditions and prohibitions on the use of equipment. Reference must be made to operator’s manuals

- personal protective equipment required, including instruction in fitting, use, cleaning, maintaining and storing this equipment

- emergency procedures, including persons with specific emergency roles and responsibilities.

- Safe work method statement (SWMS) - formwork may include construction work that is defined as high risk construction work in the WHS Regulation for which a safe work method statement (SWMS) must be prepared before the work starts. For example; erection and dismantling work activities where there is a risk of a person falling more than 2 metres.

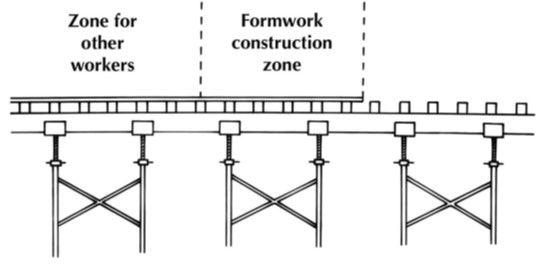

- Other trade workers – consultation between formworkers and other workers should occur prior to sign-off and handover. Edge protection should be in place, penetrations covered, safe access provided and a formwork zone set up to separate workers. The formwork zone must be sufficiently large to ensure that these other persons are clearly separated from formworkers. (See figure 1)

Figure 1: End view of deck showing working zones

Source: Formwork code of practice 2016

The control measures you put in place should be reviewed regularly to make sure they work as planned.

More information

- Formwork code of practice 2016 (PDF, 1.32 MB)

- Managing the risk of falls at workplaces code of practice 2021 (PDF, 3.9 MB)

- Formwork safety still in focus – eSAFE article

- Formwork - SafeWork NSW

Support for people affected by a serious workplace incident

For advice and support: