Hose whip on concrete pumps

Issued: 16 March 2011

Last Updated: 16 March 2011

Purpose

The purpose of this alert is to highlight the hazards and risks to workers caused by hose whip on concrete pumps.

'Hose whip' describes the uncontrolled and rapid motion of the flexible rubber hose on the end of a concrete placement boom or other concrete delivery line.

The following information is provided to assist employers, self-employed people, principal contractors, clients and project managers to meet their obligations under the Workplace Health and Safety Act 1995.

Background

A Queensland worker was fatally injured after being knocked over by a hose, which started to whip at the end of a mobile concrete placement boom. The worker fell and struck his head on a fixed steel structure. During the incident, two workers (one of whom was fatally injured) had been attempting to hold the hose horizontally.

Contributing factors

Persons can either be injured as a result of being struck directly by the whipping hose itself or being knocked over and hitting the ground or an object.

A hose whip can occur during the concrete pumping operation itself or when the line is being cleaned out. In either case, hose whip can be especially violent when air enters the line and becomes pressurised by the pumping process.

Action required

The likelihood of hose whip can be greatly reduced by the selection of suitable plant and safe systems of work. While the risk of hose whip can be reduced, additional precautions need to be taken to reduce the likelihood of injury.

To minimise the likelihood of injury from hose whip the following safety precautions are to be addressed:

- Only pump concrete that is a pumpable mix as specified by the concrete supplier. Other mixes of concrete can block the line and cause hose whip.

- Do not let the concrete solidify in the line because this will cause blockages. The concrete needs to remain in its plastic state.

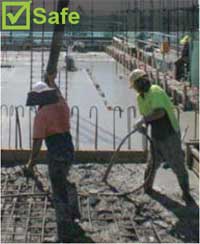

- Use well trained, competent operators to pump concrete (see examples 1 and 2).

- Start the pump up slowly to reduce the likelihood of hose whip.

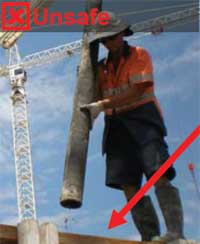

- Never attach metal fittings to the free end of the rubber delivery hose (see example 3).

- Persons not involved in the concrete pour should be excluded from the delivery hose area.

- Never try to stretch the delivery hose if it doesn't reach the pouring location (see example 4).

|  |

Example 1: line hand gently guiding hose and signalling to pump operator. | Example 2: line hand and worker operating concrete vibrator. |

|  |

Example 3: do not use metal fittings on end of delivery hose. | Example 4: workers stretching hose for additional reach. This is unsafe work practice. |

- Workers should always wear appropriate personal protective equipment, including hard hats.

- Good housekeeping needs to be maintained around the work area to reduce the likelihood of tripping.

- The delivery hose on a boom pump should hang close to vertical and only be guided by the line hand. If the boom is not long enough to reach the concrete pour area, a larger boom should be used or the concrete pump should be moved closer to the job.

- Do not let more hose hang from the boom than that allowed by the boom manufacturer (see example 5). Normally a maximum of five metres of 125 mm diameter hose can be suspended from the hose (in some cases this can be less).

|  |

Example 5: too much hose hanging from boom. | Example 6: end of delivery hose is folded over using wire to prevent concrete falling out. |

- Do not allow concrete to drop out of the hose when pumping is stopped, as this can allow air to enter the system. The hose can be folded over to prevent concrete dropping out (see example 6).

- Always ensure the line hand has an adequate sized area to stand on (the width of the working surface should be 450 mm or greater). The line hand should not stand on block walls or next to unprotected edges (see examples 7 and 8).

|  |

Example 7: pouring concrete into column form. Good access is provided. | Example 8: poor access for line hand. Access is too narrow and edge protection is not provided. |

- Monitor the level of concrete in the hopper to avoid air getting sucked into the pump system. Ensure a separate person to the line hand is in position to view the hopper. This will normally be the pump operator.

- Make sure safe work procedures are adopted for clearing blockages.

- Preferably clean out the concrete line with water instead of air.

- When there are no other options but to clean the pump line out with air, secure the end of the steel line and have an exclusion zone. All reducers and the rubber hose must be removed from the end of the delivery line. A ball catcher should be fitted to the end of the steel pipe. This will contain the blow out plug (i.e. sponge) as it is ejected from the line.

Further information

Further information is available in the Concrete Pumping Code of Practice (PDF, 1.04 MB).